Learn about manufacturing process optimization strategies that can boost your output when paired with the right measurement and analysis tools. Discover how identifying and addressing production bottlenecks, implementing predictive maintenance, and utilizing real-time data can transform your manufacturing efficiency. Leverage tools like dataPARC to gain actionable insights, ensuring your manufacturing processes are as streamlined and productive as possible.

Streamline your manufacturing operations and boost efficiency with dataPARC’s comprehensive process optimization tools.

Process Optimization in Manufacturing

Manufacturing process optimization is fundamentally about enhancing how things are done on the production floor. It’s an essential strategy for improving the efficiency of the steps and procedures contributing to the production process. At its core, process optimization aims to boost productivity and output, ensuring that resources are utilized in an effective manner.

This strategic approach involves a thorough process analysis, including the physical components. It is possible that restructuring floor plans is an outcome of the process to achieve optimal performance.

By leveraging data and descriptive analytics, manufacturers can gain insights into how elements of their process interact and influence overall productivity. This data-driven approach allows for targeted changes that can significantly enhance output.

Key areas where process optimization can have a profound impact include:

- Facility Layout: Optimizing the layout of a manufacturing facility can streamline workflows, reduce material handling times, and minimize movement, all of which contribute to increased efficiency and reduced production time.

- Inventory Protocols: Implementing smarter inventory management protocols can reduce excess stock, minimize waste, and ensure that materials are available when needed, contributing to smoother production flow.

- Equipment Utilization: Optimizing the use of equipment involves ensuring that machinery is used efficiently, maintained properly, and upgraded or replaced when necessary. This not only improves productivity but also extends the lifespan of the equipment.

By focusing on these areas, along with other physical aspects of production, manufacturers can create a more streamlined, efficient, and productive manufacturing process. This not only boosts output but also enhances the products’ overall quality and the manufacturing operation’s agility.

Manufacturing Optimization Strategies

Optimizing manufacturing processes is pivotal for enhancing productivity and efficiency in a plant. Here are various strategies that can streamline operations, reduce waste, and increase output.

Downtime Tracking:

Systematic tracking of downtime is instrumental in pinpointing patterns and underlying causes of production stoppages. Understanding when and why downtime occurs enables manufacturers to devise and apply targeted strategies to reduce these interruptions, thereby boosting operational efficiency and productivity. Initiating automated downtime tracking is a crucial step in the continuous improvement journey for enhancing production processes.

There is software whose sole job is to track manufacturing operations downtime. However, purchasing new software for each new venture can be costly. See if current software can do the job. Or, opt for integrated options that have multiple functions like real-time data analysis and production data monitoring.

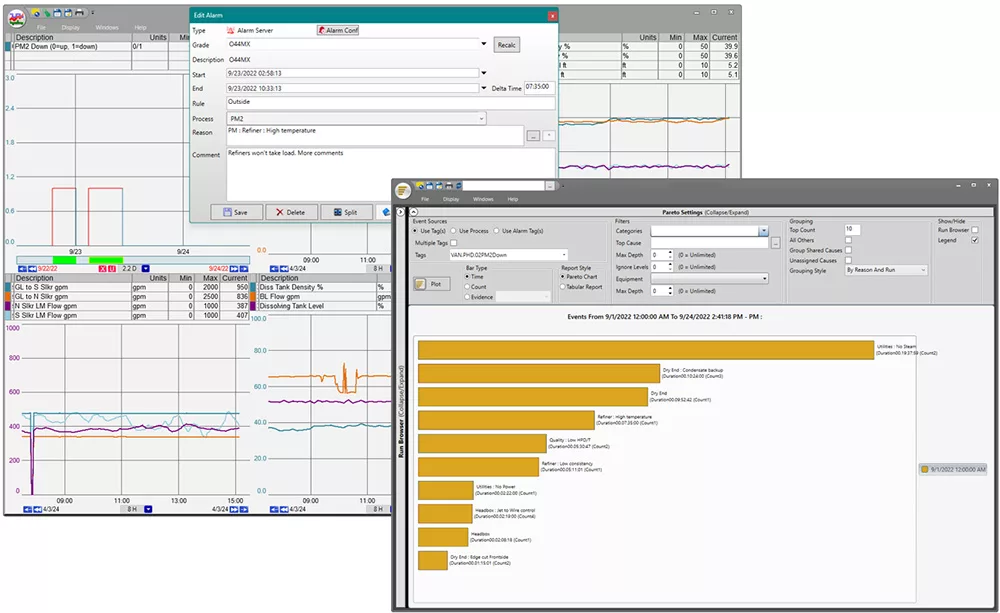

Integrating downtime tracking software with broader visualization tools, as seen with dataPARC, will increase efficiency. This integration means there’s no need for additional software investments. Manufacturing process optimization software, like PARCview, can monitor, respond to, and analyze machine downtime incidents in one place.

Effortlessly track and annotate downtime incidents directly in PARCview, enabling precise analysis and actionable insights with integrated Pareto charts for streamlined decision-making.

dataPARC’s seamless experience allows users to detect and address recurring issues within trends swiftly. Then, Pareto analysis can be used to uncover what the primary factors contributing to operational disruptions are. These tools are just a sample in the toolbox for downtime analysis and are completed in a single application, making it faster to identify top causes and reduce downtime.

Improving Maintenance & Predictive Analysis:

Shifting focus from reactive to proactive maintenance transforms the approach to equipment care, minimizing unexpected breakdowns and prolonging machine lifespan. Big data in manufacturing can help provide the needed information to create a robust maintenance schedule facilities can ensure their machinery maintains peak performance.

Maintenance schedules should be created, blending manufacturer guidelines with insights derived from real-time operational data. This approach leverages the historical performance of your equipment and aligns it with expert recommendations, yielding a tailored maintenance strategy. The risk of an expensive operational halt is greatly diminished now that the accounts of the manufacturing equipment on the production line and the manufacturer’s recommendations are combined.

By harnessing integrated real-time process monitoring, facilities can automate maintenance alerts and reporting and even tap into predictive modeling for a proactive maintenance stance.

Scheduled alerts keep maintenance tasks on track, while additional alarms notify relevant personnel of overdue actions, aiding in swiftly addressing any issues that could lead to machine failure. These reports also offer a strategic advantage and can be used to identify opportunities to replace parts nearing the end of their lifecycle during downtime. This proactive approach streamlines maintenance, ensuring efficiency even during unplanned stops.

As mentioned earlier, integrating real-time monitoring into maintenance routines helps create proactive, preventative maintenance schedules. It can also enable manufacturing companies to leverage advanced analytics and predictive capabilities when available.

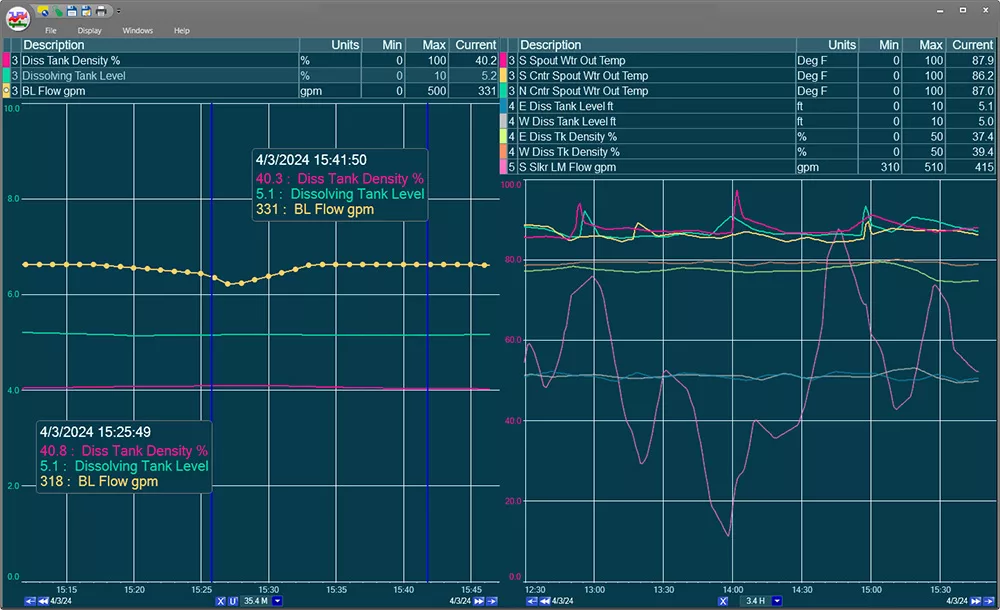

Utilize PARCview’s multi-trend feature to monitor equipment health, predict maintenance needs, and optimize your predictive analysis for enhanced operational efficiency.

Dynamic trends and visualizations continuously track how equipment is performing and identify emerging problems before they become serious. With the assistance of real-time monitoring, Maintenance can schedule machine downtime based on informed data-driven decisions. Such a proactive strategy ensures machines remain reliable and production processes stay efficient.

Implementing Workflows & Notifications Based on Machine Sensors:

Integrating IoT (Internet of Things) technology in modern manufacturing settings revolutionizes how operations respond to real-time data. Manufacturers can automate workflows and notifications based on specific operational conditions by outfitting machines with sensors. This helps ensure that potential issues receive immediate attention and appropriate actions are taken to sustain production flow.

The power of IT/OT convergence further enhances these capabilities by connecting operational technology (OT) systems with information technology (IT) platforms, allowing real-time machine data to be seamlessly integrated with enterprise-level decision-making tools. With machine sensors established, alarms can be added to them. With a system like dataPARC’s alarm system, users can set thresholds on various ‘tags’. When a limit is breached, a visual cue appears on the trend or graphic. Moreover, alarms can trigger notifications to relevant personnel, such as supervisors, and they can also initiate predefined workflows.

Beyond sending alerts, these automated workflows can perform a range of tasks. For instance, it could initiate a quality check sequence if a product parameter falls outside acceptable limits. Another example, is it could trigger a recalibration process for equipment that shows signs of deviation. Such proactive measures foster uptime and prevent minor issues from escalating into major production stoppages.

Bottleneck Analysis:

Bottleneck analysis is a critical tool for manufacturers aiming to optimize their production processes. It addresses the issue that not all stages of manufacturing take the same time or handle the same volume of product, impeding workflow. This analysis aims to pinpoint and mitigate these bottlenecks, thereby enhancing efficiency.

The process reviews how materials move through each production stage to identify where delays are likely to occur. By pinpointing these areas, manufacturers can implement targeted improvements that significantly enhance the efficiency of the production process.

Everything you need to successfully implement, analyze, & improve overall equipment effectiveness.

Utilizing data effectively is essential in bottleneck analysis. Manufacturers can pair this analysis with gap tracking. Assessing the maximum efficiency of their machines and understanding where performance may lag. This approach necessitates access to extensive historical data and the capability to analyze it effectively.

With a clear understanding of existing bottlenecks and equipment performance gaps, manufacturers can establish real-time alerts. These alerts can notify them when machine performance dips, allowing for immediate adjustments that help alleviate bottlenecks as they occur.

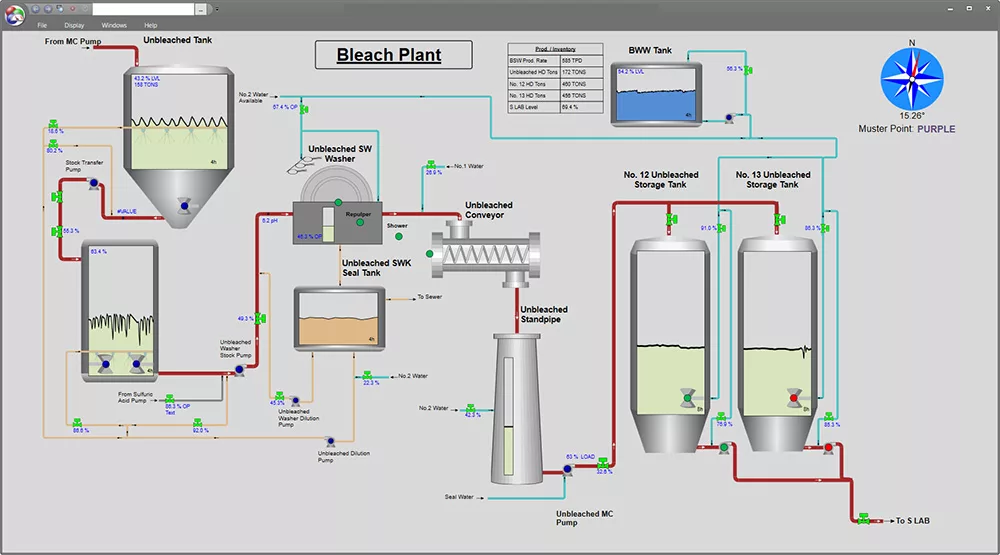

Production monitoring can help alleviate bottlenecks, and enable cross-departmental visibility by having operators outside the bleach plant monitor this graphic. This can assist with seamless operations throughout the entire facility.

Visual tools like custom dashboards also provide operators with a comprehensive view of the plant’s operations. These dashboards, which can be displayed continuously, enable operators to quickly gauge the status of various plant areas and adjust their activities to prevent potential bottlenecks. This level of insight ensures that the entire production process runs more smoothly and efficiently.

Cross-Training Employees:

Cross-training employees is an approach to bolstering manufacturing resilience and operational flexibility. By equipping staff with skills across roles and functions, manufacturers ensure that the workforce can adapt to varying production demands and mitigate disruptions due to absenteeism or turnover.

Such versatility enhances scheduling flexibility and empowers employees to monitor broader aspects of the production process.

Data competency is an important skill for cross-trained employees to have. They should be able to understand and make decisions based on operational data pertaining to the process area. Consistent operational graphics, trends, and alarms across departments in your data visualization and production system will accelerate employee learning.

Enhance cross-training with dataPARC’s intuitive user experience, giving employees what they need with real-time insights.

Cross-training employees enables them to proactively respond to upstream changes or anomalies in real-time. This proactive stance allows for quicker adjustments, reducing the reliance on supervisor notifications and minimizing the impact of communication breakdowns.

A cross-trained workforce supported by comprehensive data visualization tools can significantly contribute to sustained manufacturing efficiency and productivity.

Energy Efficiency Audits:

Energy efficiency audits can help uncover potential energy savings and promote sustainable manufacturing practices.

These audits provide a comprehensive analysis of energy usage across the manufacturing floor. They identify areas where consumption can be reduced without compromising output. Implementing the findings from these audits, such as upgrading to energy-efficient machinery or fine-tuning existing equipment settings, lowers energy costs. It also aligns manufacturing practices with environmental stewardship.

By monitoring energy usage trends in real time, facilities can identify inefficiencies that may not be apparent during routine operations. For instance, a sudden spike in energy use could indicate equipment malfunction. Consistent overconsumption might suggest a need for process recalibration or equipment updates.

Historical comparison of energy data enables facilities to measure the effectiveness of implemented energy-saving measures over time. This level of insight empowers manufacturers to make informed decisions. They can continually refine their energy usage strategies and achieve a balance between optimal production efficiency and environmental responsibility.

Manufacturing Optimization Techniques

While these techniques are widely used across various industries for process improvement, they are significant in manufacturing optimization. They are proven strategies to enhance efficiency, reduce waste, and improve overall productivity.

- JIT (Just-In-Time): JIT is a production technique that strives to improve a business’s return on investment by reducing in-process inventory and associated carrying costs, aiming to produce and deliver products only as needed.

- TQM (Total Quality Management): TQM is an approach that focuses on continuous quality improvement of products and services by involving all members of an organization, from the assembly line to the executive team.

- SPC (Statistical Process Control): SPC is a method of quality control that uses statistical methods to monitor and control a process, helping to ensure that it operates at its fullest potential to produce conforming products.

- CNC (Computer Numerical Control): CNC is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery, allowing for precise control of complex machinery like lathes, mills, routers, and grinders.

- Six Sigma: Six Sigma is a data-driven approach and methodology for eliminating defects, driving towards six standard deviations between the mean and the nearest specification limit in any process—from manufacturing to transactional and from product to service.

- VSM (Value Stream Mapping): VSM is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from its beginning to the customer, aiming to improve efficiencies and reduce waste.

Benefits of Optimizing Processes and Production

We know optimizing manufacturing processes and production streamlines operations. It also delivers a multitude of benefits that can significantly enhance the overall performance and sustainability of a manufacturing facility. Here’s a closer look at the key advantages:

- Improved Quality: Optimization leads to more consistent and reliable production processes, resulting in higher-quality products. Enhanced quality control and refined processes reduce the likelihood of defects. Thus, ensuring that the final products meet or exceed customer expectations.

- Increased Visibility: Through advanced data tracking and analysis, manufacturers gain a deeper understanding of their production processes. This visibility allows for more informed decision-making, better tracking of progress, and clearer insights into where improvements can be made.

- Efficient Resource Allocation: Optimized processes ensure that resources, whether they be materials, labor, or capital, are used more effectively. This reduces waste and maximizes the value derived from every resource invested in the production process.

- Uptime and Reduced Delays: By minimizing downtime and streamlining workflows, process optimization significantly increases operational uptime. This leads to fewer delays in production, ensuring timely order fulfillment and improved customer satisfaction.

- Cost Reduction: Streamlined and efficient processes lower operational costs. Mainly through reducing waste, minimizing rework, and optimizing the use of materials and energy.

- Enhanced Employee Satisfaction: A well-organized and optimized work environment improves employee satisfaction. Clear processes and reduced operational frustrations can lead to a more engaged and motivated workforce.

- Sustainability: Efficient use of resources and reduction in waste contribute to more sustainable manufacturing practices, aligning with environmental goals and regulations.

- Scalability: With optimized processes, scaling up production to meet increased demand becomes more feasible, as the foundation for efficient growth is already in place.

By embracing manufacturing process optimization, businesses can achieve a competitive edge by boosting productivity and quality and fostering a more agile, responsive, and sustainable manufacturing operation.