PARCserver

Process Data Historian Software

Collect plant operating data with our high-speed process data historian systems. Access manufacturing data from different sources on a single trend for troubleshooting and analysis.

High-Speed Time Series Data Storage

PARCserver’s data collectors utilize “store and forward” technology to buffer data from multiple sources, ensuring maximum data integrity. Utilize hundreds of OPC and custom servers to interface with your automation layer.

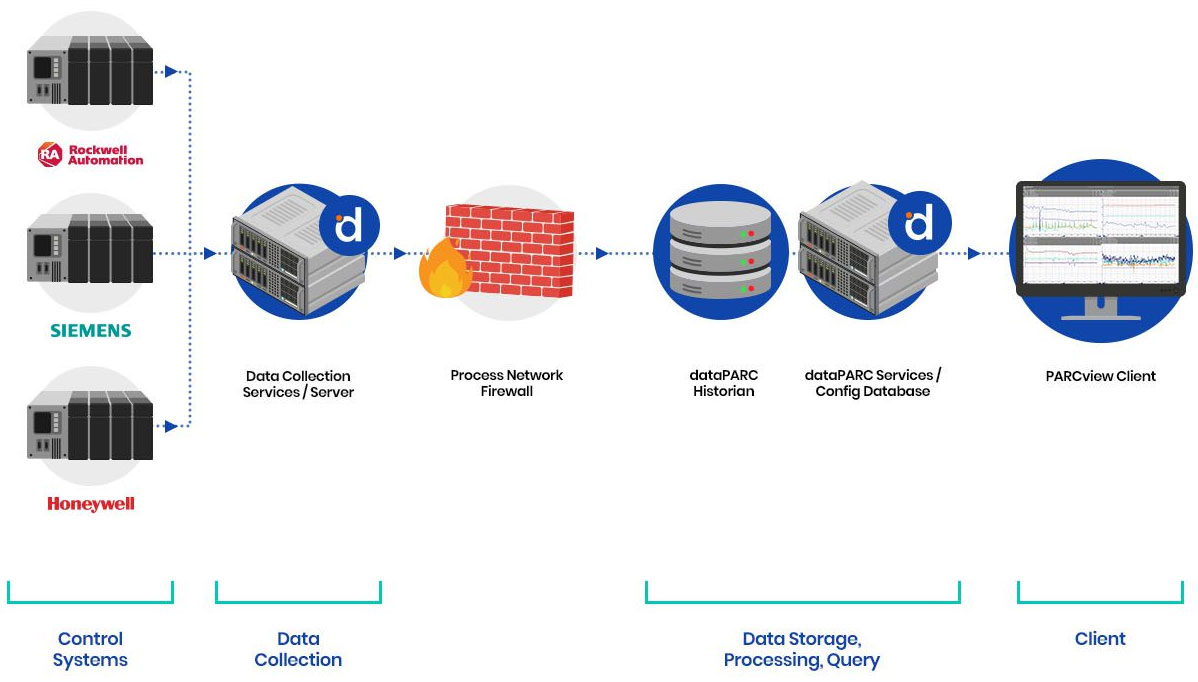

Standard Implementation

dataPARC’s operational historian collects & records high-frequency industrial process data from all the automation systems & control systems in your plant.

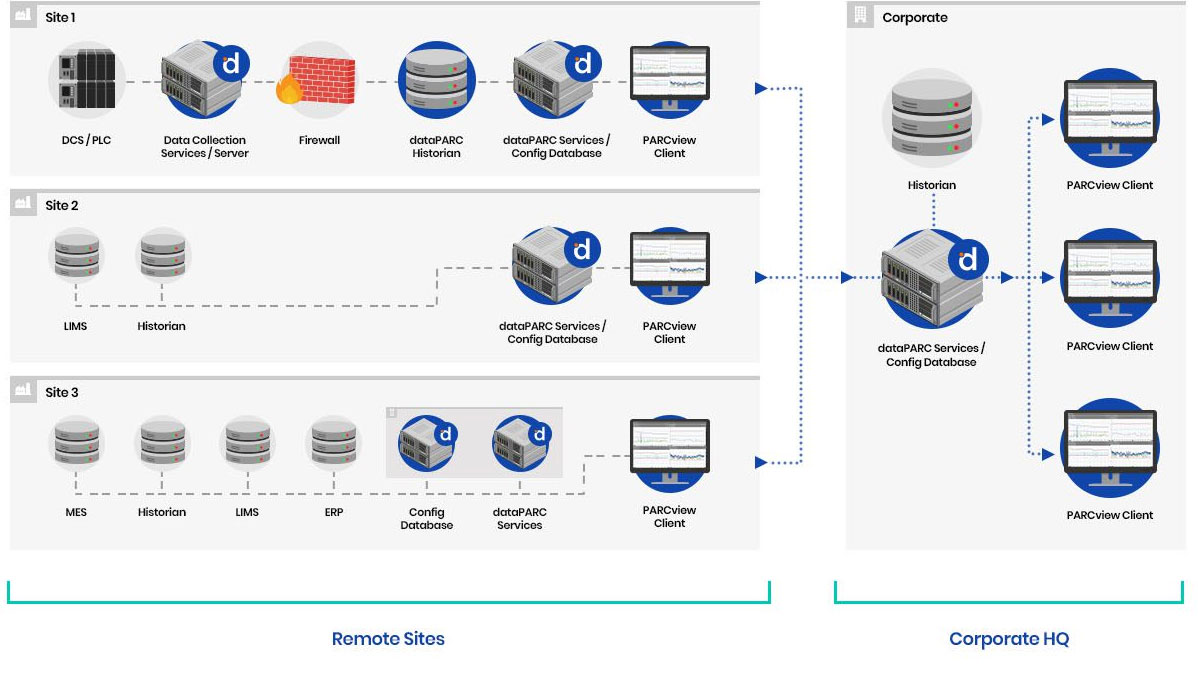

Enterprise Implementation

Integrate dataPARC’s enterprise data historian in multi-site operations.

Dive Into The Data

dataPARC’s process historian is designed to optimize large amounts of real time data for high speed data collection and analytics performance. Connect all your systems to collect data at a single site, or aggregate data across multiple sites for enterprise-wide visibility.

- Combine IT & operations data for better visibility.

- Collect PLC & control data.

- Connect to standard SQL databases for lab & quality data.

- Integrate IT data from MES, etc.

- Share data between sites easily.

Flexible Enterprise Architecture

Make all data perform like it’s local. dataPARC’s process data historian is designed for increased operational performance and reduced data and administration costs. Achieve improved efficiency and productivity with streamlined resources that give you access to your manufacturing data when and where you need it.

Smart Data Collection

PARCserver leverages machine learning to automatically roll-up or compress data based on usage, freeing up critical disk space.

Minimize Bandwidth on WAN

Reduce network load by offering higher-performance, low-bandwidth data to corporate users until high resolution site-level data is requested.

Smaller Corporate Footprint

Provide optimized, high-performance data for enterprise access, reducing the need for costly hardware infrastructure at corporate HQ.

Rapid Remote Access

Quickly view optimized aggregate data at corporate & remote sites, while maintaining instant access to lossless, high resolution production data.

Auto Archiving

PARCserver povides instant online access to 100% of your historical data while also automatically archiving older (5-10 years) data to less expensive storage drives.

Scale Tags at Lower Cost

Get an Enterprise-class historian at a fraction of the cost. PARCserver is a cost-competitive process data historian suitable for all systems.

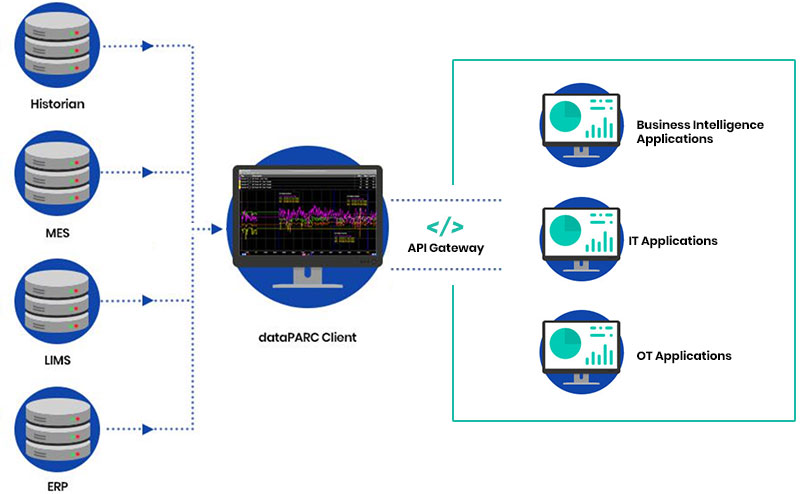

Push Processed Data Anywhere

Analyze, filter, & generate modeled values from your data with dataPARC, then use our single-point API to push the processed data to your current IT, OT, or business intelligence applications.

“We consume nearly a dozen external data sources that help us enrich our data: weather data, power data, pricing data… dataPARC allows us to get more value of what we already have.”

Tyler Fedun, Manager IT Operations – Energy Transfer

Video Tour

Kapstone Paper

The global containerboard market is highly competitive, making process optimization essential to a paper mill’s survival. KapStone’s technical team turned to dataPARC to help them centerline their process, identify golden runs, and lower operating costs.

Powering Practical Analytics Solutions for 25+ Years

We were trying to optimize the largest facility in our company and PARCview allowed us to overlay data – both lab and process – to break down perceptive barriers and make data-driven decisions.

Stan Case

Plant Manager – Amalgamated Sugar

Our investment in dataPARC is allowing us to focus on system optimization as we leverage the data we are now capturing.

Tyler Fedun

Manager IT Operations – Energy Transfer

We make a lot of different different grades of paper. In order to maximize the dollars for each run, we use dataPARC’s centerline tool to find ‘golden runs’ and those become our target each time we run a grade.

Pami Singh

Director Process Optimization

The World’s Largest Manufacturers Depend on dataPARC

Related Solutions

Take control of critical plant performance data with dataPARC’s real-time data visualization and analytics software. Tackle industrial data challenges with PARCview’s out-of-the box functionality.

Data Integration

Establish a single source of truth for all your raw production data. Historian, ERP, MES, lab, & more.

Quality Control

Real-time quality assurance and control tools for continuous or batch manufacturing processes.

Data Historian Features

dataPARC is a flexible industrial analytics toolkit built upon the promise of easy data acquisition & integration. dataPARC’s core building blocks can be used to build any applications to meet your needs.

Real-Time Trending

Widely considered the best process trending application available, PARCview provides a combination of powerful features and ease of use for data collection, data analysis and troubleshooting. Key features include drag & drop, dragging time-axis, time syncing of multi-trends, multi-trend templates, and more.

Dashboards & HMI Displays

Create high-performance HMIs and enterprise dashboards to display your operational process data. Create animated displays by associating object properties (size, color, background, foreground) with tag values. import existing dashboard graphics from PI, IP.21, and more.

Dynamic Alarms & Notifications

Use dataPARC’s rule-based alarm and event engine to build smart alarm definitions that reliably detect compliance events, including data loss, real time, and aggregate exceedance of regulation limits. Forward alarm and event data to PARCview’s Logbook, and send notifications via email or SMS.

Manual Data Entry Tools

PARCgraphics Designer’s form-based MDE tools offer a platform for constructing custom data entry screens. Enter data against a record from anywhere within the dataPARC environment, across multiple MDE pages, PCs, and locations.

Batch Analysis Tools

Arrange multiple batches by product into a comparison or consecutive view. Search for historical batches based on identifying information, such as batch ID or product label. Determine variability at any point in the batch using Run Trend analysis.

Control Charts

Build control charts (x-bar, range, standard deviation, etc.) from existing sources or PARCview formulas. Define simple min/max limits, choose from Western Electric Rules or custom logic. Limits can be managed natively in dataPARC or imported from a 3rd party database.

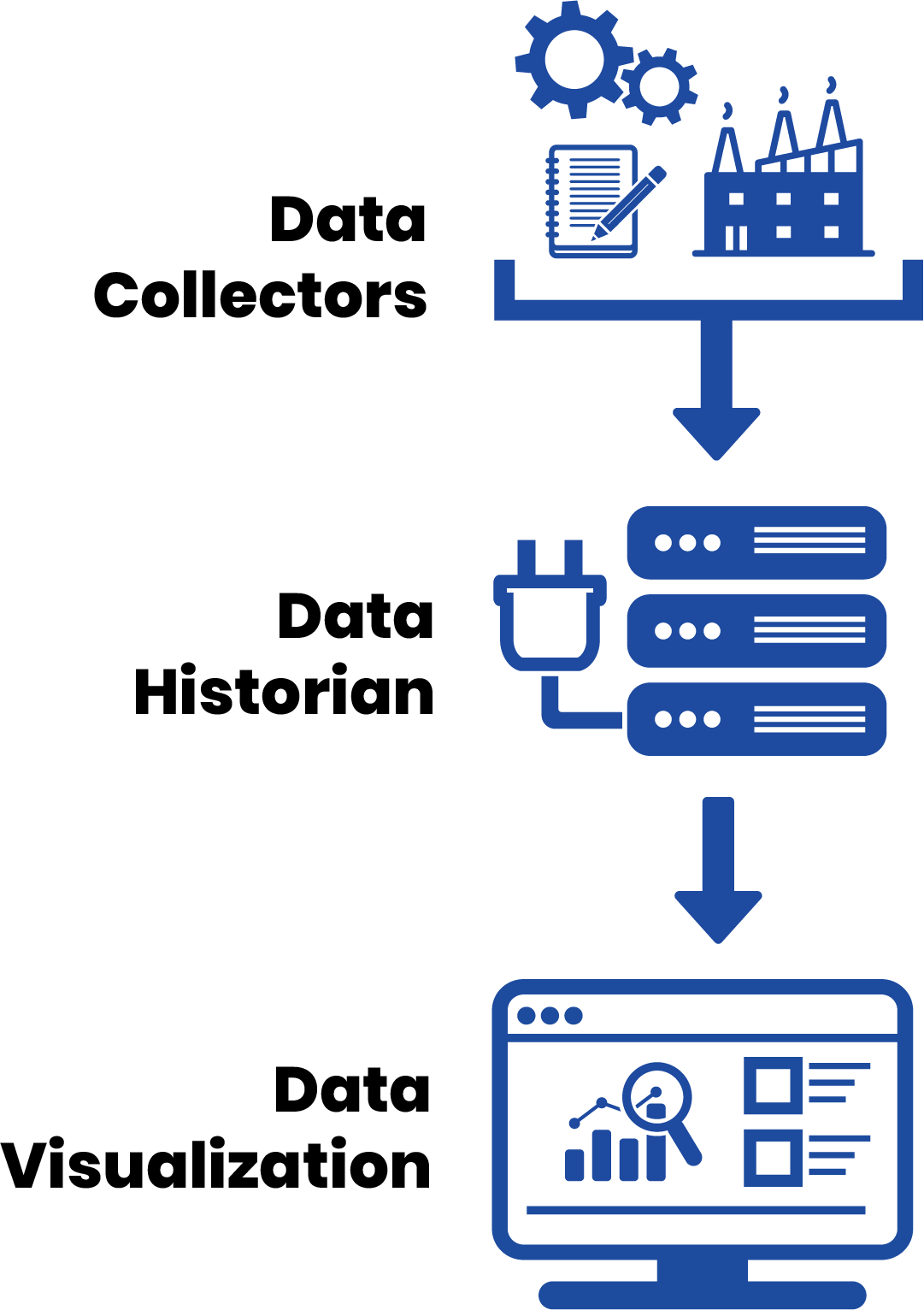

Understanding Data Historians

Data historians are specialized systems designed to collect, store, and manage large volumes of raw data generated by industrial processes. These systems serve as repositories for plant data, capturing information from various sensors, machines, and equipment involved in manufacturing or other industrial activities to store time series data. This provides a comprehensive record of industrial process data, allowing organizations that store historical data to analyze performance trends, identify inefficiencies, and make informed decisions to optimize operations.

Access to this data enables the measurement of key performance indicators (KPIs), providing valuable insights into the performance of equipment and processes. This empowers organizations to identify trends, troubleshoot issues, and enhance overall operational effectiveness. KPIs often include parameters specific to industrial process concerns, including increasing production rates, reducing energy consumption, equipment performance monitoring, lowering operating costs, quality control measures, and more.

When used with specialized tools and interfaces, such as PARCview, data historians allows users to query, analyze, and visualize the stored data. Visualizing industrial process data facilitates informed decision-making based on the trends and patterns of historical data. The combination of effective data storage and data access makes data historians crucial for optimizing industrial processes.

Want to Learn More?

Download the datasheet to learn more about dataPARC’s operational data historian software.

- Data Collection & Storage Functions

- Enterprise-Ready Architecture

- High Performance Features

- Security and Admin

- 3rd-Party Use-Cases