Operating Envelopes

Effectively compare all process parameters versus the appropriate targets (The Envelope), allowing the plant to reduce variability and avoid potentially harmful conditions.

Probable Comparisons

Our Centerline gives an at-a-glance comparison of current process variable values or historical aggregates against defined reliable operating ranges.

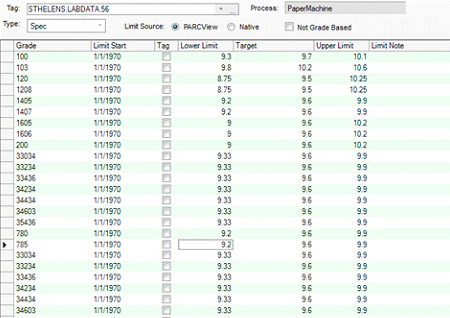

Configure The Envelope

Multiple limits can be established for each process data tag, and can even be associated with scripted and calculated tags. Tag limits can be entered directly as number values, reference calculated tag values, or use values imported from external databases. Furthermore, limits can be grade- specific, product-specific, or rate-specific.

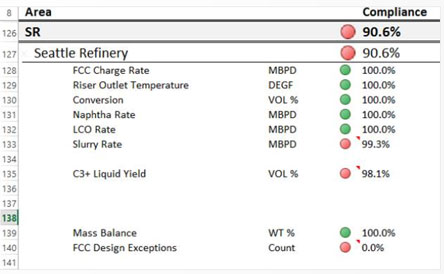

Compliance Reporting

Generate reports on critical process and equipment variables. These reports can include the percentage of time each variable was within its limits or centerlines, information on individual out-of-centerline events, and “rollup” percentages for different groups of data over a specified period of time (daily, weekly, monthly, etc.).

Universal Limits & Alarms

Limits and alarms that are set up in PARCalarm can be accessed from other dataPARC applications, including Trends, Graphics, Centerlines, Logbook, Histograms, and SQL Reports.

- Control limits calculated from historical data

- Limits based on OEM design specifications

- Environmental and/or governmental compliance limits

- Customer specification/product quality limits

Want to Learn More?

Click the links below to recieve a FREE PDF on the solutions dataPARC has to offer for Operating Envelopes.