This article explores the key considerations for a GE Proficy replacement. We’ll discuss the benefits of alternative solutions like dataPARC, including improved data visualization, scalability, user interaction, and integration capabilities. Whether you’re looking to boost data speed, simplify user access, or embrace AI and ML technology, this guide will help you make informed decisions for your manufacturing site’s data strategy.

Build Real-Time Dashboards & Displays for Effective Process Monitoring with dataPARC

GE Proficy encompasses a suite of industrial software solutions, including the Proficy Historian for data collection and storage and the Operations Hub for data analysis and visualization. Some users have noted challenges with quick data connections and certain functionalities, which may not fully meet the needs of all manufacturing operations.

As Artificial Intelligence (AI) and Machine Learning (ML) become increasingly central to manufacturing strategies, organizations are seeking tools that facilitate the seamless integration of these technologies. For facilities currently utilizing GE Proficy, this may represent an intermediate stage in their digital transformation journey, where data is available but not yet fully leveraged for advanced analytics.

Exploring alternatives to GE Proficy could be beneficial to continue progress toward AI and ML integration. dataPARC offers a comprehensive solution with its data Historian and PARCview visualization tool, designed to provide robust and user-friendly data management and analysis capabilities. This integrated approach can support manufacturers in advancing their digital transformation and achieving their process optimization goals.

Enhancing Data Access and Speed

One powerful way to boost data speed and improve integration availability is by transitioning to a new historian. Doing so can open up more options for connecting diverse data sources and further digitizing your plant. However, replacing your historian isn’t the only way to achieve faster data access and improved performance.

PARCview, the visualization and analysis side of the dataPARC suite, is a robust program that excels in delivering rapid data recall and analysis. Unlike many other visualization tools, PARCview can seamlessly “sit on top” of your existing data historian and significantly accelerate data retrieval. This enhanced performance is driven by dataPARC’s Process Data Engine (PDE).

PDE works by aggregating data so that when users request large sets, such as weeks or months of data, it optimizes the data points it pulls without altering the overall data profile. This means that your data’s critical highs and lows remain intact, ensuring data integrity during analysis.

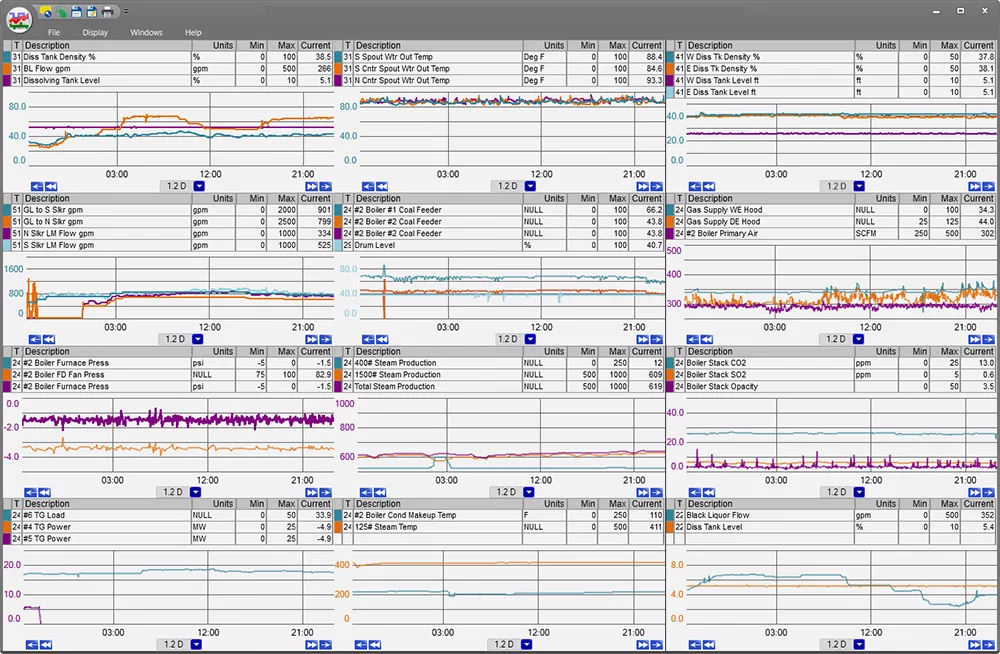

Quickly compare data across sources in a multi-trend. Data integration and access to comprehensive historical data allow for efficient analysis and decision-making.

The result? Even when retrieving up to six months of data, which might take minutes with other visualization tools, PARCview delivers it in seconds. This responsiveness ensures that users can access information at the speed of thought, removing frustrating wait times and supporting faster, more informed decision-making.

The best part is that this powerful functionality is included in the default PARCview package. Users don’t need to pay extra for enhanced speed or efficiency—it’s simply part of the dataPARC experience.

Optimizing Data Visualization for Real-Time Decision-Making

Another essential consideration is the data visualization tools available at your site. How are engineers and operators accessing and interpreting data? Are operators relying solely on log and on DCS screens for monitoring and troubleshooting? This approach can be tedious and prone to oversight, as it often allows only one trend to be viewed at a time, making it easy to miss subtle process changes.

Data visualization software such as Operations Hub or PI Vision may already be in place for more advanced facilities. These tools can provide operators with better access to data. However, in today’s fast-paced digital age, it’s crucial to ask: Are these tools comprehensive enough to support real-time, data-driven decision-making? If the answer is no, it may be time to explore more robust alternatives that empower your team to visualize complex data efficiently and make quicker, more accurate operational decisions.

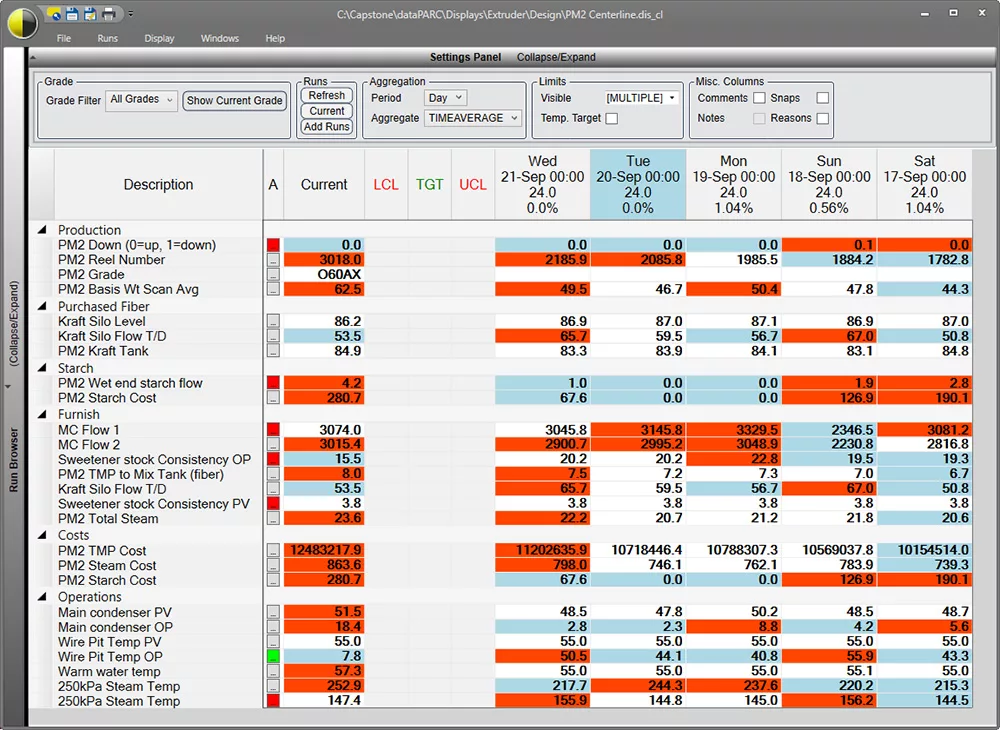

Monitor process performance in real-time with dataPARC’s centerline display, featuring color-coded indicators highlighting averages above (red) or below (blue) typical run values. This unique functionality supports quick decision-making and process optimization, setting dataPARC apart from tools like GE Proficy.

Simplifying User Interactions for Greater Efficiency

A common issue reported by GE Proficy and Operations Hub users is the complex configuration and challenging usability of these tools, as noted on review sites like G2. For those considering GE’s systems, it’s essential to recognize how ease of use impacts buy-in from operations teams. If operators find the program difficult to use and avoid engaging with it, the data’s value to the site diminishes significantly.

For users currently working with GE tools and seeking to replace them with a more intuitive alternative, dataPARC offers a solution that prioritizes user interaction and seamless functionality. PARCview, part of the dataPARC suite, incorporates user-friendly features that make accessing and navigating data straightforward. Quick access through right-click menus and double-click and click-and-drag capabilities are integrated throughout the software.

For example, if you have a tag displayed and want to add it to a trend, you can simply click and drag it. Need to explore the data further? Just double-click on any tag to open a pop-up trend and dive deeper. These thoughtful interactions make data analysis easier and quicker, ensuring operators can engage with data efficiently and make better-informed decisions.

Ensuring Scalability and Cost Effectiveness

One of the common challenges for industrial sites is ensuring that everyone who needs access to data can obtain it without prohibitive costs. Pricing models vary significantly between companies; some base their costs on the number of users, while others consider company size or the level of data access needed. At dataPARC, we believe that it’s your data, and everyone who needs it should be able to access it. That’s the reason why we don’t employ complicated pricing structures that limit data access or restrict the number of users.

With dataPARC’s pricing model based on tag count, scalability becomes straightforward. Whether you are looking at simply upgrading tools or going with a fully new data historian. The system is designed with tag ranges in mind, so adding a few extra tags won’t push you into a higher pricing tier—it typically requires a significant increase in tags to necessitate a license upgrade.

This flexibility allows you to integrate additional systems, such as lab data or shipping data, without worrying about escalating costs. You can extend access to more users while maintaining various security levels as needed, breaking down data silos and empowering everyone to share and access reports and confirm information independently. This means the site can control who has access to raw data, reports, and notes, ensuring operations aren’t the sole gatekeepers.

Both PARCview and the historian are highly scalable, accommodating everything from single-site operations to multi-site enterprises. This even extends to providing corporate-level access to critical customer data, ensuring seamless integration across the organization. With dataPARC, you get complete control of your data without limitations based on licensing size—enabling you to access all your data all the time.

Tips for Transitioning from GE Proficy

Working on digital transformation at your plant? Let our Digital Transformation Roadmap guide your way.

If you decide to replace your current system and that is the best step for your site, here are a few important considerations to keep in mind:

Experience with Replacements and Integration

Does the new company you’re considering have proven experience replacing GE Proficy Historian and Operations Hub? If you choose not to replace the historian, ensure the new software can integrate seamlessly and “sit on top” of your existing historian. Be aware that some solutions can only connect to their proprietary historian, forcing you to replace both systems.

Carefully consider whether this approach aligns with your site’s needs and long-term goals. If you choose only to have a new visualization tool installed, evaluate any potential integration concerns for future data connections. Will the software support access to third-party platforms that enable advanced AI and ML analysis?

Ease of Adoption

Will your employees be able to learn and use the new software quickly? Choosing a system that supports your team in making real-time, data-driven decisions is essential. Consider metrics like the Workflow Productivity Index (WPI), which measures how efficiently users can move from an initial question to an actionable response or answer. This metric is particularly important in fast-paced manufacturing environments, where timely data-based decisions are critical.

By addressing these questions and ensuring a smooth transition, you can position your site for greater success as you move beyond GE Proficy.

Moving from GE Proficy to dataPARC

When considering replacing GE Proficy and Operations Hub, dataPARC is an excellent option. The dataPARC team has extensive experience ensuring a smooth transition for companies looking to move away from GE. The intuitive software offers increased functionality that allows users to access more features, potentially saving money while expanding end-user access across the site.

Moreover, dataPARC can integrate seamlessly with third-party systems, enabling advanced AI and ML applications when your site is ready for those capabilities. At dataPARC, manufacturing process data visualization and historian tools are our focus and passion. This specialized focus means we deliver the features that engineers need, designed by engineers for engineers.

Conclusion: Taking the Next Steps

Finding a GE Proficy replacement to an alternative solution can be a pivotal step in advancing your site’s data capabilities. There is no point in waiting. By exploring tools like dataPARC, which offer intuitive interfaces, robust visualization, and seamless integration with existing and future systems, your team can make data-driven decisions more efficiently. Ensuring that your new solution supports scalability and user adoption and provides a foundational data ecosystem for AI, including advanced analytics like ML, will be crucial for long-term success. Embracing this shift means empowering your operations to harness data effectively, unlocking greater insights, and streamlining workflows across the board.

If you’re ready to enhance your site’s data strategy, evaluating your options and selecting a solution tailored to your needs will help set the foundation for continued growth and innovation.