In this blog, find a replacement for GE Digital’s Operations Hub that will fit your site. Navigate through essential considerations that pave the way for a seamless transition to a new visualization software. Uncover a path toward enhanced operational efficiency and data-driven decision-making.

Build Real-Time Dashboards & Displays for Effective Process Monitoring with dataPARC

Data visualization is integral to manufacturing. It allows for data-driven decision-making and provides opportunities to optimize operations. Visualization tools allow operations to identify patterns, discover hidden correlations, and make informed choices that impact efficiency and productivity.

Manufacturers using outdated visualization tools may run into challenges and could be missing some cutting-edge benefits.

If you are reading this article, you want to explore what else is out there besides GE Digital’s Operations Hub. Whether you are searching for a faster product, or something more reliable and user-friendly, we will outline the leading solutions on the market.

The Need for Replacing Operations Hub

GE is a large company, juggling numerous divisions. Users of Operations Hub have raised valid concerns about its usability and adaptability.

Feedback on sites such as G2, has highlighted the challenges posed by Operations Hub complexity, data connection speed and limited features. The call for more data, faster is a trend across industries. Companies are seeking robust systems that can provide users with data quickly.

At such a large company, how much customer feedback can they act on?

In the age of manufacturing digital transformation, there is a drive to replace slower technology with the latest and greatest. The desire for a streamlined user experience aligns with the mission to address the limitations of current software. Replacing it to ensure that the chosen alternative is fast and user-friendly.

These alternatives are more than just a replacement; they are a leap forward in embracing the evolving needs of manufacturing industries.

Seamless Transition: Replacing Operations Hub with PARCview

PARCview is an excellent choice as an alternative to GE Digital’s Operations Hub. It aims at empowering process industries through its comprehensive data visualization and analytical capabilities.

User-Friendly Interface

At the core of PARCview’s appeal lies its user-friendly interface, effectively bridging the gap between process engineers and operators.

This interface simplifies the complex task of data interpretation, ensuring that insights generated are accessible to a wider array of stakeholders. Real-time, interactive multi-trends can be created in seconds of opening the software.

dataPARC’s software package also comes with advanced analytics, so users can track KPIs, conduct root cause analysis, and monitor their operations.

PARCview’s Trend is the #1 trending tool on the market. It is fast and user-friendly.

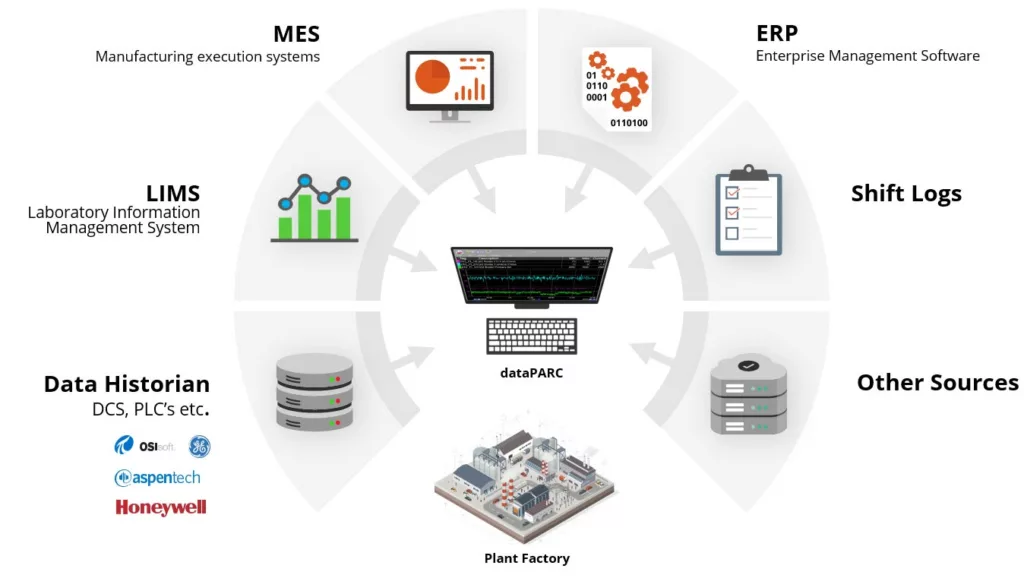

Data Integration

One of PARCview’s standout features is its seamless integration with diverse data sources, enabling real-time insights that facilitate well-informed decision-making. This integration overcomes the limitations of traditional data silos, presenting a unified view where different data streams converge.

Scalability

Adaptability and scalability are pivotal in the always changing landscape that is manufacturing. In this regard, PARCview excels, seamlessly accommodating manufacturing operations of varying scales and across diverse industries.

It is important that everyone at your site has access to the data they need. Whether overseeing an extensive production line or managing a specialized operation, PARCview’s adaptability is well-suited to accommodate the unique demands of each endeavor.

Other Replacements for Operations Hub

There are a variety of options to consider when looking for alternations to Operations Hub for your data visualization needs.

Seeq:

Seeq specializes in advanced analytics tailored for process manufacturing data. With its diagnostic capabilities, Seeq is a good replacement option. It empowers users to delve deep into their data, offering performance optimization. Whether it’s tracking equipment performance or fine-tuning processes, Seeq’s capabilities align with the evolving needs of modern manufacturing.

Canary:

Tailored specifically for the process industries, Canary is a data visualization and analytics software. Its array of features encompasses real-time monitoring, advanced analytics, and reporting. It can enhance operational optimization and efficiency.

TrendMiner:

TrendMiner is a self-service industrial analytics software, facilitating the analysis of time-series data from various sources. It has advanced data visualization, pattern recognition, and predictive analytics capacities. TrendMiner enables the identification of process inefficiencies and the fine-tuning of performance.

Further Considerations for Operations Hub Replacements

Transitioning from GE Digital’s Operations Hub to an alternative, like PARCview, is a transformative journey. It is important that this process is seamless, to keep operations moving and users board with the new software.

Making a seamless transition from Operations Hub to another data visualization software requires careful planning and execution. Here are some further considerations to ensure a smooth and successful transition:

Comprehensive Assessment:

Begin by conducting a thorough assessment of your existing data infrastructure, processes, and requirements. Identify the specific functionalities and features that are essential for your operations.

Training and Familiarization:

Provide comprehensive training sessions for your team members to familiarize them with the new data visualization software. This includes not only operators but also engineers and IT who will be responsible for maintaining and troubleshooting the software.

Integration with Existing Systems:

Check the compatibility of the new software with your existing systems, such as MES, SCADA, or ERP systems. Seamless integration is vital for a cohesive operational ecosystem.

Connect all your systems data for a single source of truth.

Data Security and Privacy:

Ensure that the new software complies with data security and privacy regulations specific to your industry. Data breaches and non-compliance can lead to significant operational disruptions.

Explore, invest, and embrace the potential of advanced data visualization tools. By doing so, you enhance your manufacturing excellence, promoting efficiency, precision, and enduring success.

Final Thoughts on Replacing Operations Hub:

Embracing the shift from traditional manufacturing data visualization tools to cutting-edge alternatives is an essential step towards achieving operational excellence. As we conclude this exploration, it’s clear that the landscape of data visualization is evolving rapidly, offering innovative solutions to meet the ever-changing needs of modern manufacturing.

In this journey, we’ve highlighted the imperative to replacing Operations Hub with more adaptable and user-friendly options.

The call for streamlined interfaces and real-time insights is growing louder, echoing the demand for faster, more insightful data analysis. Solutions like PARCview offer user-friendly interfaces, seamless integration, and scalability that align with manufacturing industries.

Remember that transitioning from a familiar tool to a new platform is more than just a change – it’s a transformation that requires careful planning.

As you explore the alternatives, invest in the right solution, and embrace the potential of modern data visualization tools.