This blog explores the essential aspects of Industrial Environmental Monitoring, emphasizing its role in promoting safety, efficiency, and compliance in industrial settings. It highlights the significance of monitoring various environmental parameters and integrating advanced equipment and software.

Check out our advanced analytics tools & see how you can quickly optimize your processes.

Environmental Monitoring for Industrial Plants

Environmental monitoring in an industrial context involves systematic sampling and analysis of various environmental parameters. This ensures and protects industrial operations’ safety, efficiency, and compliance. This practice is pivotal in the industrial sector for several reasons, each contributing to the overall sustainability and operational excellence of a facility.

At its core, environmental monitoring in industrial plants refers to continuously assessing environmental factors such as air quality, temperature, humidity, gas concentrations, and pH levels. This process involves collecting data through various instruments and technologies. To understand the environmental impact of industrial activities and ensure that conditions remain within safe and acceptable limits.

Importance in the Industrial Industry:

Safe Working Environment:

Maintaining a safe working environment is paramount in industrial settings. Environmental monitoring helps identify hazardous conditions. Conditions such as toxic gas leaks or extreme temperature fluctuations. Reducing or eliminating these conditions will ensure the health and safety of workers and prevent workplace accidents.

Energy Usage Monitoring:

By closely monitoring energy consumption patterns through environmental and energy monitoring, industries can identify areas where energy is wasted. This insight is crucial for implementing measures to reduce unnecessary energy consumption, leading to more sustainable operations.

Energy Efficiency Measures:

Environmental data can drive the implementation of energy efficiency measures. Insulating pumps and HVAC systems, optimizing heating and cooling processes, and ensuring machinery operates within energy-efficient parameters. These actions not only conserve energy but also significantly reduce operational costs.

Regulation Compliance:

Adherence to environmental regulations is a critical concern for industrial plants. Environmental monitoring ensures that industries comply with legal standards related to emissions, waste disposal, and pollution, thereby avoiding hefty fines and legal repercussions.

Pollution Prevention:

By continuously monitoring environmental parameters, industries can prevent pollution at its source. This proactive approach helps minimize the release of pollutants into the surrounding air, water, and soil, contributing to a cleaner and more sustainable environment.

Early Detection of Environmental Risks:

Monitoring acts as an early warning system, detecting potential environmental risks before they escalate into serious issues. This detection is crucial for implementing timely interventions, mitigating risks, and protecting both the environment and the facility’s assets.

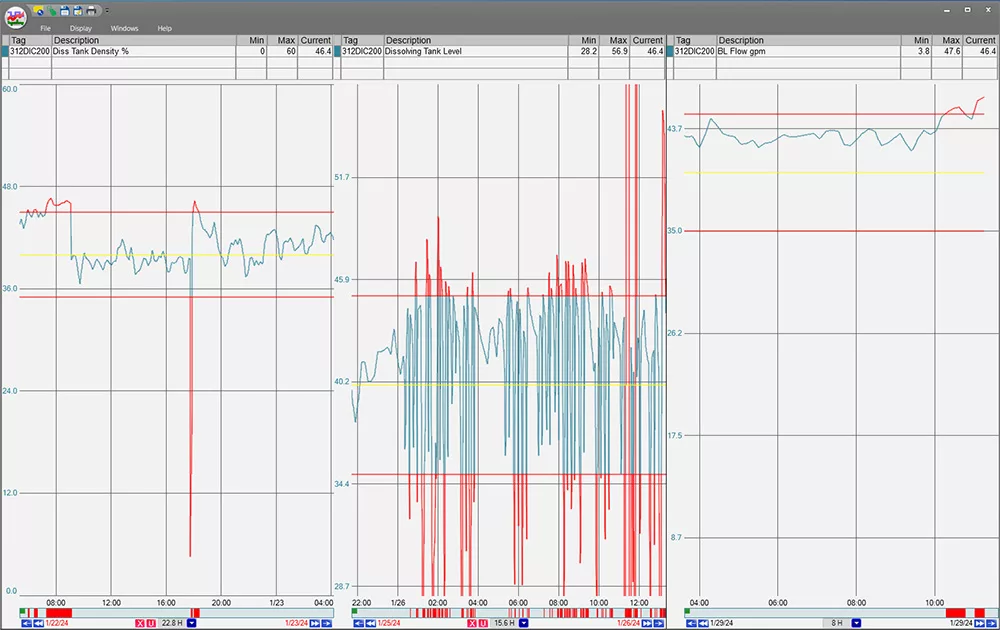

PARCview empowers users to promptly identify when variables deviate from their specified limits, enabling them to activate alerts via email or text messages. This ensures that the right individuals can take swift action, maintaining optimal operational standards

In conclusion, environmental monitoring is an indispensable part of industrial operations, intertwining safety, sustainability, and compliance. As industries evolve and environmental standards become more stringent, the role of sophisticated environmental monitoring solutions, encompassing both advanced equipment and technology, will continue to grow in significance.

Environmental monitoring encompasses a variety of parameters, each critical to understanding and optimizing the industrial environment. These parameters include air quality, pressure, humidity, gas concentrations, temperature, and pH levels, all of which are vital for ensuring operational safety, efficiency, and regulatory compliance.

Types of Environmental Monitoring in Industrial Settings

Achieving Environmental Excellence: Your guide to environmental KPIs, strategic practices, and more!

Air Quality

Air quality monitoring is essential for detecting pollutants and contaminants in industrial settings, such as particulate matter, volatile organic compounds (VOCs), and other hazardous substances. Maintaining good indoor air quality is crucial for worker health, preventing respiratory issues and other health problems. Instruments like air samplers and analyzers are used to assess air quality, ensuring it meets occupational health and safety standards.

Pressure

Monitoring pressure in industrial environments is vital for equipment’s safe and efficient operation, especially in processes involving compressed gases or fluids. Pressure sensors and transducers are used to ensure that systems operate within safe limits, preventing leaks, explosions, and equipment malfunctions.

Humidity

Humidity levels can significantly impact manufacturing processes, affecting product quality and machinery operation. Too much humidity can lead to corrosion, condensation, and mold growth, while too little can cause vibration, static electricity problems, and material brittleness. Hygrometers and humidity sensors help maintain optimal humidity levels, safeguarding both the production process and the work environment.

Gas

Gas monitoring is critical for detecting the presence of combustible, toxic, or asphyxiant gases, which pose significant health and safety risks. Utilizing gas detectors and analyzers to continuously scan the environment for dangerous gas concentrations is important. They will trigger alarms and activate ventilation systems when necessary to mitigate risks.

Temperature

Temperature control is pivotal in industrial settings, as extreme temperatures can affect worker safety, equipment functionality, and product integrity. Thermometers and thermal imagers monitor temperature variations in critical environments, ensuring conditions remain within specified thresholds for safe and efficient operations.

pH

In industries where chemical processes are prevalent, such as pharmaceuticals and manufacturing, monitoring the pH levels of solutions is crucial. Incorrect pH levels can lead to process inefficiencies, equipment damage, and safety hazards. pH meters and sensors provide precise measurements, allowing for the adjustment of processes to maintain the desired chemical balance.

Build Real-Time Dashboards & Displays for Effective Process Monitoring with dataPARC

By closely monitoring these environmental parameters, industrial facilities can optimize their operations, ensure the safety of their workers, and meet regulatory requirements. Advanced environmental monitoring solutions, including a combination of sophisticated equipment and integrated software platforms, provide the comprehensive oversight needed to maintain optimal conditions and drive continuous improvement in industrial settings.

Environmental Monitoring Solutions

Effective environmental monitoring in industrial settings relies heavily on integrating sophisticated solutions, encompassing specialized equipment and comprehensive software systems. These tools are essential for capturing, analyzing, and managing environmental data, enabling industries to maintain compliance, ensure safety, and enhance operational efficiency.

Equipment

The foundation of any environmental monitoring system is the equipment used to measure various parameters. This includes a wide range of sensor equipment that monitors air quality, pressure, humidity, gas concentrations, temperature, and pH levels. Each type of sensor serves a specific purpose and needs to be strategically installed throughout the industrial plant to ensure accurate and representative data collection.

For instance, air quality sensors might be placed near potential sources of emissions or in areas where workers are most likely to be exposed to harmful substances. Temperature and humidity sensors, on the other hand, are often distributed across different zones of a facility to maintain optimal conditions for both machinery and personnel. The installation of this equipment requires careful planning to cover all critical areas, avoid interference with operations, keep energy costs low, and ensure the sensors’ longevity and accuracy.

Software

While individual sensor equipment plays a crucial role in environmental monitoring, the true power lies in integrating these multiple data sources into a cohesive, reliable, and easy-to-manage system. This is where environmental monitoring software comes into play, offering a unified platform that connects disparate sensors and provides a comprehensive overview of environmental conditions in real-time.

General Software Features:

dataPARC’s platform provides real-time data visualization, customizable dashboards, and advanced analytics capabilities, making monitoring environmental parameters and identifying trends or anomalies easier.

dataPARC software exemplifies this integration, offering customers a suite of features designed to streamline environmental monitoring.

Early Detection:

The software’s real-time monitoring and alert systems enable prompt detection of environmental deviations, allowing for prompt response to potential hazards or inefficiencies, thus safeguarding both the workforce and the environment.

Reporting Capabilities:

dataPARC also offers robust reporting features, simplifying compliance reporting and internal performance reviews. Automated report generation and the ability to customize reports to meet specific regulatory requirements or internal benchmarks ensure that stakeholders are always informed and equipped to make data-driven decisions

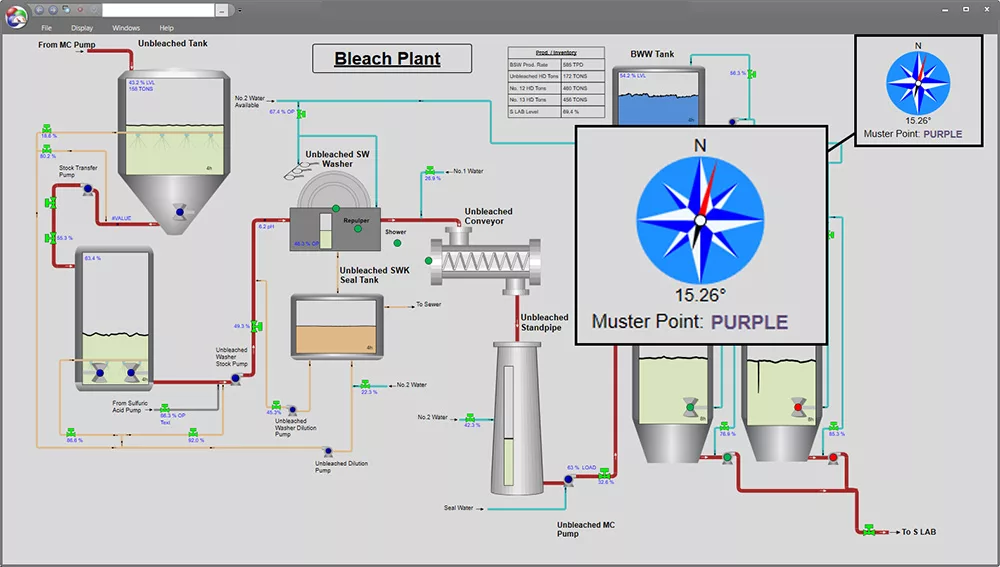

Real World Use Case:

In a practical application, one customer with outdoor chemicals has dataPARC integrated with a wind direction sensor. They use this tag on a graphic to enhance their safety protocols. By displaying wind direction, the operations always know the safest evacuation routes in the event of an emergency. This is a prime example of using real-time environmental conditions for operational safety.

dataPARC dashboards are highly customizable. Additionally, if a site doesn’t have weather tags, this data can be connected to PARCview via weather.gov.

In summary, the link between sensor equipment and software like dataPARC creates a robust environmental monitoring solution for industrial plants. This combination enhances the accuracy and efficiency of environmental monitoring efforts. It also supports a proactive approach to environmental management, ensuring safety, compliance, and sustainability in industrial operations.

Key Insights: Navigating Industrial Environmental Monitoring

The journey through the various types of environmental monitoring, from air and water quality to pH levels, underscores the complexity and necessity of keeping a vigilant eye on multiple environmental parameters.

Equipping industrial plants with the right monitoring equipment is the first step toward developing an environmental management system. The proper installation of sensor equipment across a facility lays the groundwork for comprehensive data collection. This enables a detailed understanding of the environmental impact of industrial operations.

However, the true potential of environmental monitoring technology is unlocked by integrating this equipment with software like dataPARC. Consolidating data from various sensors into a unified platform transforms raw data into actionable insights. Features such as real-time monitoring, early detection alerts, and automated reporting capabilities streamline environmental management processes and empower industries to respond proactively to environmental challenges.

In conclusion, the path to effective industrial environmental monitoring is paved with a combination of sensor equipment and software solutions. By embracing these environmental monitoring efforts, industries can pave the way for safer, more efficient, and more sustainable operations.

FAQ: Industrial Environmental Monitoring

1. Why is environmental monitoring necessary in manufacturing?

It helps facilities stay compliant with regulatory requirements, avoid fines, reduce environmental impact, and build a more sustainable operation. Monitoring also provides data to support process improvements and risk mitigation.

2. What are common types of environmental data monitored in industrial settings?

Typical data includes emissions (e.g., CO₂, NOx, SO₂), effluent discharge volumes and quality, hazardous waste levels, energy and water consumption, and ambient air or noise levels.

3. How is environmental monitoring data collected?

Data is collected through sensors, manual lab sampling, and online analyzers. This data is often integrated into software platforms, such as dataPARC, that provide real-time dashboards, trend analysis, and historical reporting.

4. What regulations does environmental monitoring support?

Monitoring supports compliance with environmental standards and regulations such as the U.S. EPA’s Clean Air Act, Clean Water Act, and state or regional permits. It also supports internal goals like ISO 14001 certification or ESG reporting.

5. What are the challenges of environmental monitoring in industrial facilities?

Common challenges include siloed data systems, lack of real-time visibility, manual reporting processes, and inconsistent data quality. These barriers make it harder to track trends and respond to issues quickly.

6. How does environmental monitoring support sustainability initiatives?

By providing detailed data on resource usage and emissions, environmental monitoring helps companies set and track sustainability goals, reduce their carbon footprint, and report progress to stakeholders.

ESG Environmental Excellence Guide

A comprehensive guide focusing on key environmental KPIs, strategic practices, and how software can support impactful environmental strategies for sustainable operational success.