As the impending discontinuation date of Rockwell Automation’s VantagePoint draws near, manufacturers find themselves presented with a unique opportunity for exploration and evaluation to search for replacements. This blog not only outlines the consideration of alternatives but also delves into recommendations that pave the way for a seamless and successful transition.

Check out dataPARC’s real-time process data analytics tools & see how better data can lead to better decisions.

VantagePoint End of Life

Data management is pivotal to the industrial world and software often becomes a benchmark of innovation. However, as technology advances, so do the demands for more robust solutions.

Rockwell Automation’s FactoryTalk VantagePoint, has announced the end of life. For industrial operations, where efficiency and precision are paramount, the departure of any software necessitates a strategic pivot. For those using VantagePoint, it has helped them run their plants for years. They must make proactive decisions on what steps to take to replace VantagePoint. The question is, with what?

As we delve into the blog, our purpose is clear: to navigate this juncture with users seeking alternatives, unraveling the possibilities that lie beyond VantagePoint, and navigating pathways to the next era of industrial data management and manufacturing analytics.

VantagePoint Replacement Timeline

Rockwell Automation declared the discontinuation of VantagePoint, effective March 2025. This foresighted announcement provides manufacturers with a crucial window for exploration and evaluation, encouraging a thoughtful consideration of alternatives.

Whether opting to remain within the Rockwell ecosystem or seizing the opportunity to venture into new and innovative solutions, consider an opportunity to extend your digital transformation journey and upgrade your system with the newest technology.

Considerations for VantagePoint Replacements

Rockwell Automation’s FactoryTalk VantagePoint has been in industrial operations since 2008, fostering familiarity among users over the past 15 years. Navigating the prospect of change can be challenging, especially when a software solution has become integral to your operations. As you search to find a suitable VantagePoint replacement, it’s crucial to consider key features that have made it central to your site. Here are some parameters to consider when researching alternative software:

1. Self-Configuration Dashboards, Trends, and Reports

End-users are able to self-configure dashboards and trends with VantagePoint and report easily with SQL Server Reporting Services (SSRS). This is not the case with all operations management and visualization software. Be sure to look out for tools that allow for unlimited user licenses, access to dashboard configuration, and step-by-step tutorials for users to learn as they go. This could reduce or eliminate waiting for others to assist with such requests.

2. Seamless Access to Production Information

It is important to remember that VantagePoint is a process and operations management tool rather than an advanced analytics or predictive analytics tool. Its replacement must have some of these features as well. Consider this when looking at new products such as Augury or ControlRoomAI. They could be missing some of the key exploratory and data management that was being done with VantagePoint. Additionally, ensure that the new tool provides simple data export to Excel for analysis and management, similar to the accessibility of VantagePoint.

3. Alarm and Event Management

FactoryTalk VantagePoint had multiple versions available; if you had the Line Edition (LE), Alarms and Event management might be another key factor. Be sure that any software you navigate to will be able to replace your alarming features that were done in VantagPoint, as losing these process alarms would be a major step back in your site’s continuous improvement efforts.

Real time production montioring and managing alarms efficiently, ensures timely responses and enhanced operational safety.

4. Extensive Connectivity and Data Sources

Replacement software must continue to connect data sources together. Many will have third-party connectors, enabling access to data from native and OPC DA real-time devices, OPC HDA historians, and popular historians like GE Proficy Historian and OSI PI Historian, but could also include other sources such as text files or SQL connections.

5. Web-Based Interface

FactoryTalk VantagePoint is accessible through a web-based interface. If companies wish to continue down this road, they may see fewer features than in some of the desktop alternatives. Some companies have both or just one to choose from. This will also be another decision point.

6. Other Areas to Consider: Engage Current Users

While the considerations outlined above provide a solid foundation, it’s equally crucial to engage with your end-users, operators, engineers, and existing VantagePoint users. Conduct interviews or surveys to identify the specific features and functionalities they find most valuable in their day-to-day tasks. Understanding their priorities will ensure that your new software not only meets the technical requirements but also aligns with the practical needs of those who rely on it the most. This user-centric approach will help with a smooth transition and widespread adoption of the replacement software within your organization.

Potential VantagePoint Replacements

dataPARC

As you navigate potential replacements for VantagePoint, dataPARC stands out as an excellent and versatile solution that seamlessly addresses key functionalities crucial to your manufacturing operations.

Self-Configuration Dashboards, Trends, and Reports

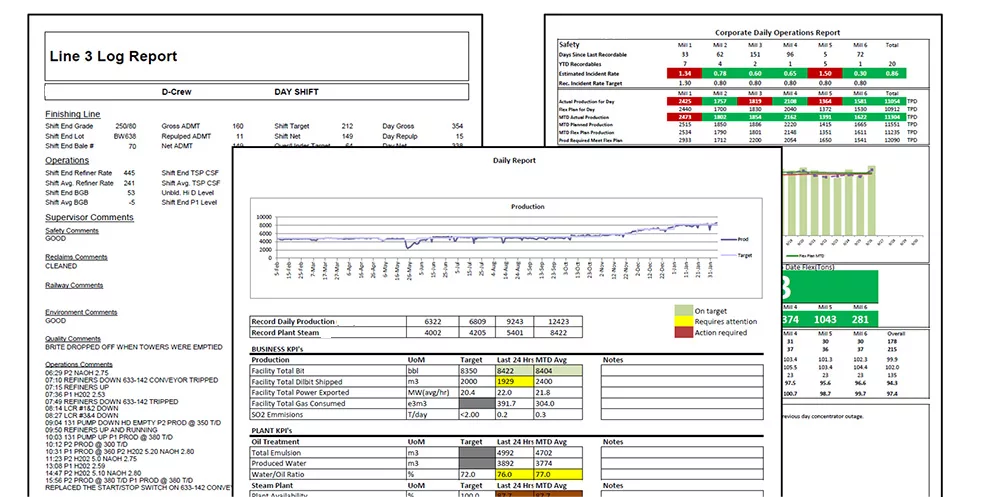

Unlike some operations management and visualization software, dataPARC empowers end-users with the ability to independently configure dashboards, trends, and reports. Offering unlimited user licenses and access to comprehensive dashboard configurations, dataPARC provides step-by-step tutorials, enabling users to learn and implement without dependencies on support resources. This ensures a swift and efficient process, reducing or eliminating the need for external assistance. Beyond dataPARC’s own reporting, it seamlessly connects to SSRS, allowing reports to maintain the same look and feel.

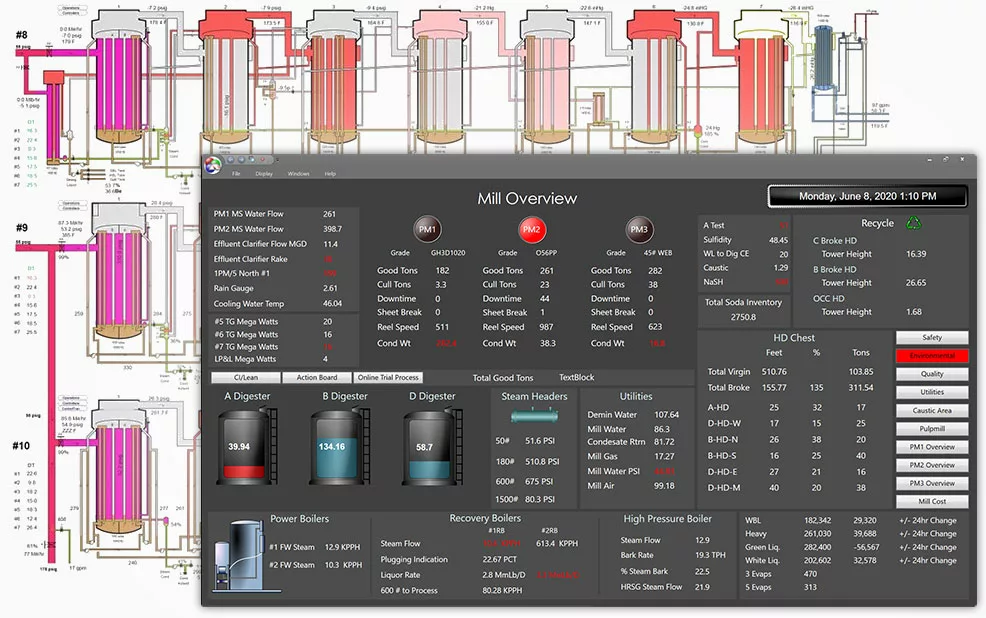

Dynamic graphics and dashboards provide real-time data visualization, enabling users to monitor, analyze, and optimize operational performance with ease.

Seamless Access to Production Information

Recognizing that VantagePoint primarily serves as a process and operations management tool, dataPARC goes beyond by integrating advanced analytics and data management features. With dataPARC, you can replace your VantagPoint system and get some added features along the way. The Excel add-in is equally powerful and user-friendly, allowing users to pull time series data for further analysis and reporting.

Whether you prefer using the dataPARC itself, Excel, or SSRS. Enjoy flexible and powerful reporting options tailored to your needs.

Alarm and Event Management

If your site has been utilizing the Line Edition (LE) of VantagePoint with a focus on Alarms and Event Management, dataPARC ensures a seamless transition. Retaining and enhancing these critical features. Downtime tracking, emailing alarms, and sending reports are all accessible within the user interface.

Extensive Connectivity and Data Sources

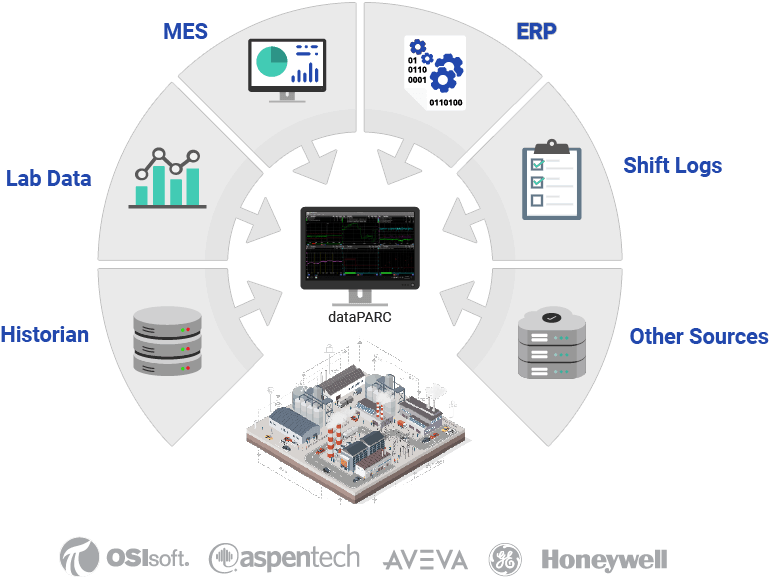

dataPARC not only supports third-party connectors for native and OPC DA real-time devices, OPC HDA historians, and popular historians like GE Proficy Historian and OSI PI Historian but also extends its connectivity to include sources such as text files and SQL connections. This versatility ensures that your data integration needs are comprehensively met.

View your data in one place with PARCview’s data integration

Web-Based Interface

While dataPARC’s primary interface is that of a desktop application, it does have a secondary product that allows for web-based data interaction. This adaptability becomes a significant decision point for organizations with diverse user preferences.

In essence, dataPARC should be on your list when looking into different replacements for VantagePoint. It addresses each critical aspect with a commitment to user empowerment, data connectivity, and comprehensive functionality. The transition to dataPARC not only ensures the continuity of essential features but also opens avenues for enhanced data exploration and analytics within your manufacturing environment.

DataView

Another suitable option for FactoryTalk VantagPoint replacement is FactoryTalk Analytics DataView. This is another product in the FactoryTalk family and one of Rockwell Automation’s suggestions on their site. An advantage of going with an in-house transition is staying with the same company and staying to what you know.

DataView is a step up from VatagePoint as it offers a more user-friendly interface that enables data visualization and configuration. Much like VantagePoint, DataView allows users to configure dashboards and reports. By switching to another product in the same family one would imagine a smooth transition for VantagePoint users, allowing them to continue leveraging their past expertise.

The robust connectivity features of DataView make it a good replacement for VantagePoint. Supporting various data sources and integration protocols, DataView ensures a seamless transition for users accustomed to VantagePoint’s data connectivity capabilities.

ThingWorx

Another option on the VantagePoint replacements list Rockwell is suggesting is ThingWorx, it is yet another one of their product line.

ThingWorx offers advanced analytics and predictive capabilities, elevating it beyond the scope of VantagePoint. For users who found value in exploratory data analysis and predictive analytics within VantagePoint, ThingWorx presents an opportunity to enhance these capabilities. Be sure to check that all legacy systems are compatible.

ThingWorx distinguishes itself through seamless integration with the Internet of Things (IoT) and edge computing technologies, making it a cutting-edge solution for manufacturers at the forefront of Industry 4.0 adoption. By utilizing ThingWorx, users can tap into the potential of IoT data, gaining deeper insights into production processes and empowering proactive decision-making. However, it’s essential to consider whether this advanced technology aligns with your current operational readiness. Investing in capabilities beyond users’ immediate needs or preparedness may raise questions about the cost-effectiveness of adopting features that might not be fully utilized in the present context.

Transitioning to VantagePoint Replacements

Navigating the transition from FactoryTalk VantagePoint to a new operational data platform can be a daunting task. Here are a few tips to help with the transition and encourage users to embrace the changes to come seamlessly:

Assessing VantagePoint Replacement Factors:

Like make of the other factors we included in the above section, your site might also want to consider Scalability, ease of integration, and long-term support as you evaluate replacement options.

Software scalability ensures the chosen solution aligns with the growth trajectory of your operations. How easily the new software integrates with existing and legacy systems is important to avoid frustrations and operational disruptions. Finally, long-term support is important, in five years you don’t want to be in the same place again.

End User Training

Regardless of which software is chosen it is important to train end users to adequately use the new program. Take what you learned from earlier interviews and surveys, and be sure those core topics are covered during training. Make sure end users know where to go if they have questions.

Migration Strategies

There are many migration approaches, but change management and creating a plan will help create a smooth transition. Develop a well-thought-out migration plan to minimize downtime and avoid data loss during the transition. You might not stick exactly to what was laid out but you will have a road map to work from.

Conclusion

The farewell to Rockwell Automation’s FactoryTalk VantagePoint signifies a pivotal moment for industrial operations. With over a decade of service in plant operations, the discontinuation of VantagePoint demands proactive decisions on what steps to take next.

Those seeking VantagePoint replacements must engage with their end-users, operators, and engineers to align with technical requirements and the practical needs of those integral to daily operations. It is a big decision that needs to take place, and it’s not just a change in software; it’s a transformative journey toward continued innovation and operational excellence.