Case Study

Korea Western Power

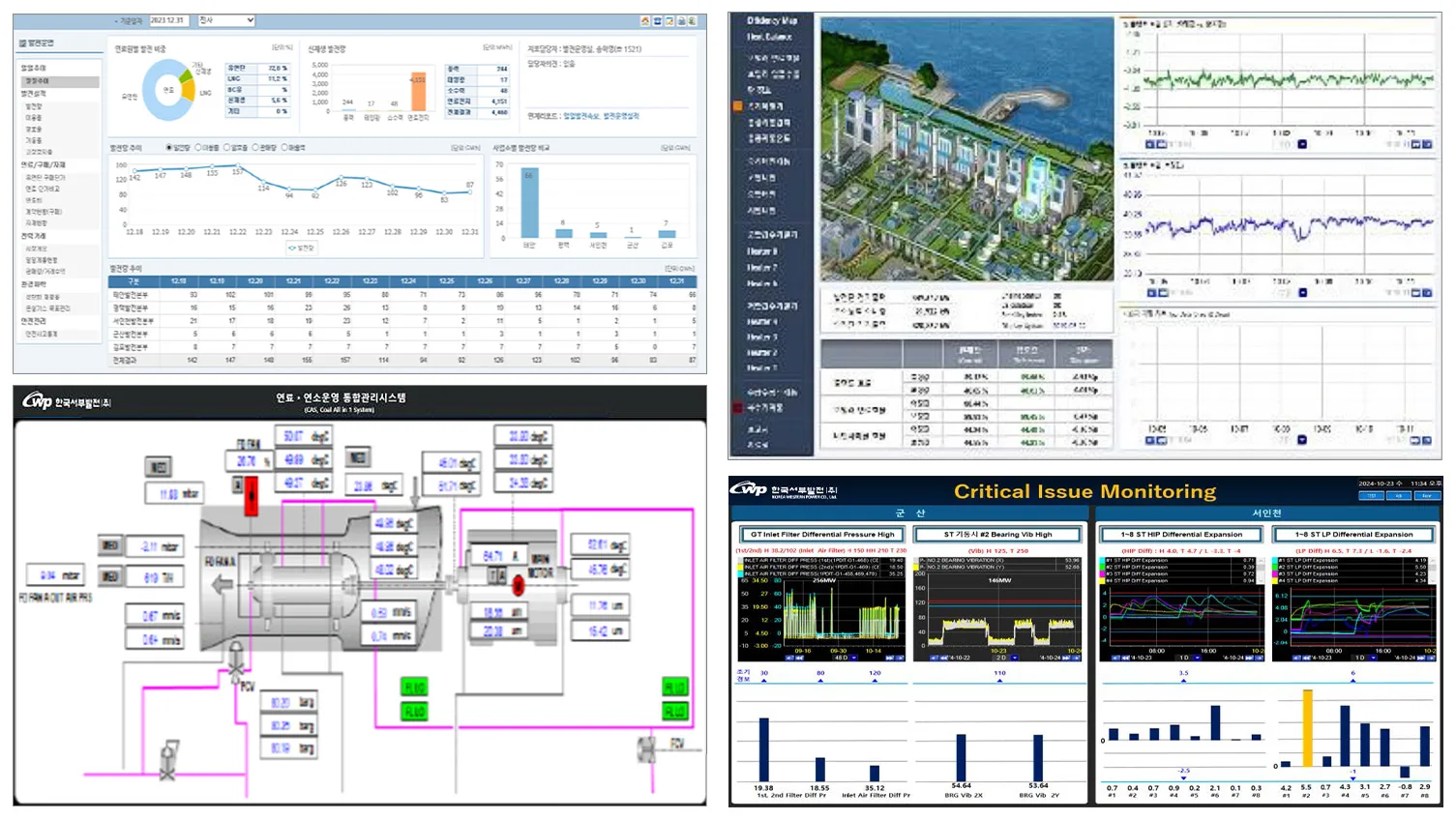

After struggling with performance issues from their existing PI System, Korea Western Power achieved enterprise-wide connectivity, improved process monitoring, and faster decision-making by switching to dataPARC.

Korea Western Power’s Story

Founded in 2001, Korea Western Power (KOWEPO) is a subsidiary of Korea Electric Power Corporation and one of South Korea’s leading power producers. With an installed capacity of over 11,000 MW, the company generates approximately 10% of the nation’s electricity through a portfolio of coal, LNG, and renewable energy facilities. In 2023, their total annual power generation exceeded 41,000 GWh.

Korea Western Power operates across multiple plants and employs more than 2,350 people. Among its facilities is the Taean Thermal Power Station, one of the largest coal-fired plants in the world, underscoring the scale and complexity of its operations.

“dataPARC allowed us to monitor all company power facilities in real time and implement fault prediction.”

Korea Western Power’s Challenges

Prior to adopting dataPARC, Korea Western Power relied on the PI System for process analytics. However, PI’s slow performance made it difficult to access long-term trend data—critical for effective root cause analysis. Without timely access to this information, engineers faced delays in troubleshooting and resolving process inefficiencies, raising risks of costly downtime and reduced reliability in power generation.

Connectivity was another major concern. With more than 6,000 displays across multiple plants, KOWEPO required a unified user interface and consistent data access enterprise-wide. At the same time, the company placed a premium on high-quality visualization without sacrificing the volume of data available. Their legacy system struggled to meet these combined demands for speed, scalability, and visualization.

The dataPARC Solution

Process Integration

In 2016, Korea Western Power began migrating from PI to dataPARC. Local plants quickly saw improvements in both performance and visualization through PARCview’s intuitive analysis tools and the enhanced processing power of PARCpde (Performance Data Engine).

Dashboards and OEE

Korea Western Power also implemented Operation Information Monitoring, which delivered real-time process visualization, and incorporated Logic Builder’s drag-and-drop interface, making it simple for sites to connect and access data universally.

Predictive Intelligence

By 2018, a central Monitoring and Prognostic (M&P) Center was established, integrating data from all remote plants. Using an Intelligent Predictive Analysis System (IPAS), the center provided early warnings for plant disturbances, supported root cause analysis, and enabled proactive process troubleshooting—transforming how KOWEPO managed its generation fleet.

Results

Korea Western Power transformed its WISE Predictive Diagnosis Center into a fully integrated operational framework for intelligent and insightful monitoring across diverse operational conditions. By connecting previously independent systems—including iPASU, OIS, PMS, AGS, WPDP, CAS, RMS, GENi, and WTUBE—dataPARC enabled seamless integration of technical, operational, and business management data into one unified platform.

This integration gave Korea Western Power company-wide visibility into power generation, facility stability, performance metrics, and profitability. The upgraded WISE system now serves as a centralized platform that simplifies access to critical information, allowing users to monitor and manage operations through a single, cohesive interface.

More Success Stories

Energy Transfer

See how Energy Transfer underwent a complete digital transformation, saving them time, money, and enabling better decision-making.

W.R. Grace

Learn how W.R. Grace integrated their IT & OT data, eliminated data silos, and made production data available to everyone in the company.

Western Plains Energy

See how Western Plains Energy developed data-driven insights and improved product quality and process efficiency at their ethanol plant.

Korea Western Power Case Study

See how Korea Western Power achieved enterprise-wide connectivity, improved process monitoring, and faster decision-making by switching to dataPARC.