Case Study

Kuantum Papers LTD.

Kuantum Papers LTD. strategically implemented PARCview and dataPARC Historian to optimize operations, utilizing real-time data monitoring and streamlined consolidation processes.

Introduction

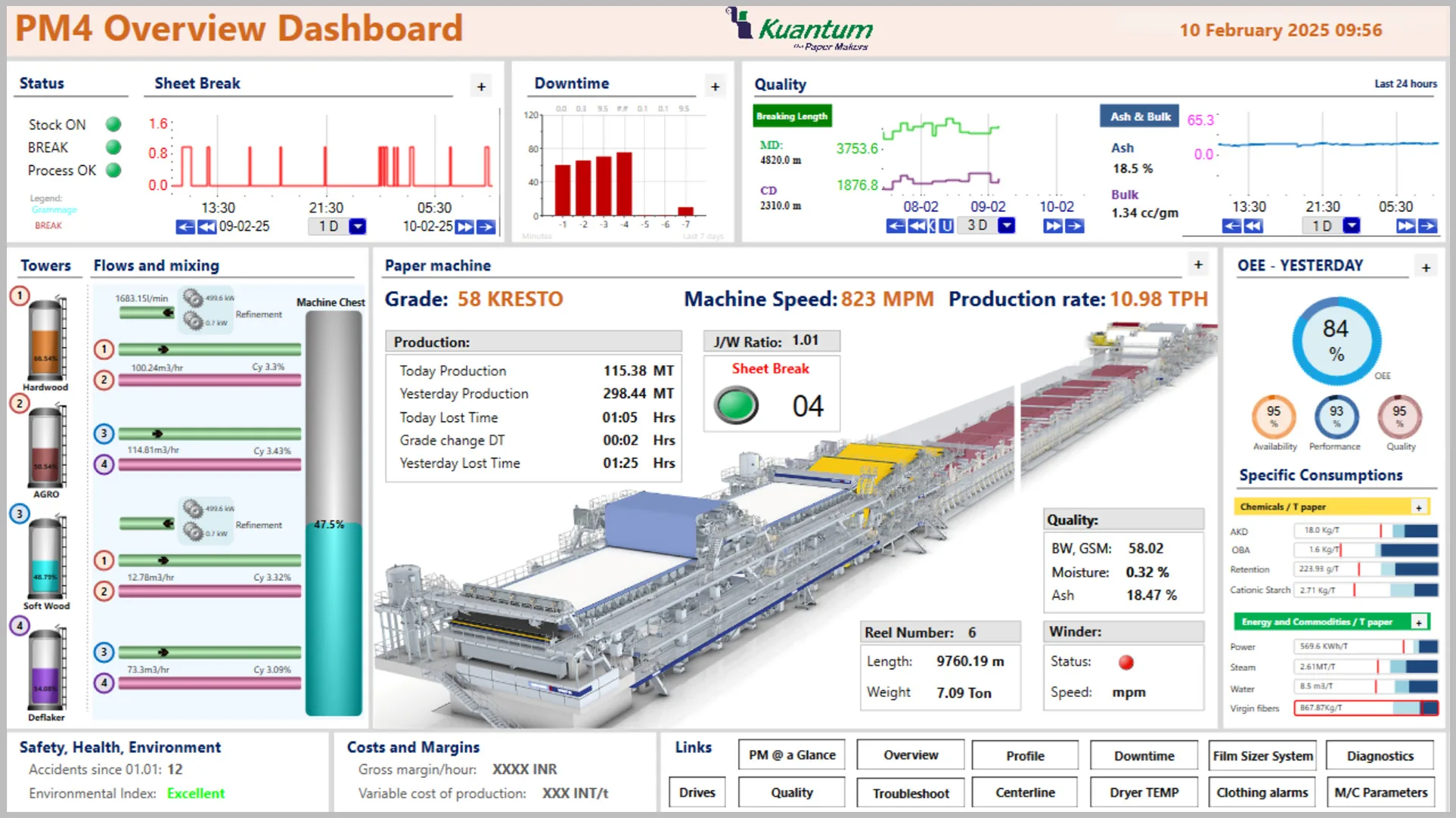

Kuantum Paper implemented a full mill-wide dataPARC solution, connecting over 35,000 tags from more than 14 different systems, including SAP, into a single, unified platform. With real-time integration of process data, lab results, and business systems, teams can now visualize operations from a single source of truth.

“It was a good first step to get dataPARC mill wide; it broke down barriers and helped us cross horizons.”

Pavan Khaitan, Vice Chairman & Managing Director, Kuantum Paper

Initial Challenges

- Implement real-time data sharing across the entire plant

- Integrate over 14 data sources into a single platform

- Build dashboards to deliver real-time overviews of major KPIs

- Create a shared understanding of operations from shop floor to leadership

- Focus the initial rollout on critical reports and KPIs to drive quick wins

- Create a foundation for the long term vision of making mill wide optimization using APC tools

“dataPARC is a far better tool to visualize, time align, & analyze data than using Excel sheets. This allowed improved data utilization to fast-forward descisions. To achieve this, improving our foundation of data was very important.”

Pavan Khaitan, Vice Chairman & Managing Director, Kuantum Paper

dataPARC Solutions

Centerline The Process

The site applied centerlining by production rate on the paper machine, pulp mill, and power and recovery areas to drive consistent operations and reduce process variability.

Golden batch for Consistency

By highlighting “Golden Runs“ they streamlined the papermaking process by enabling engineers to fine-tune recipes and formulas based on long-term, grade-specific trend data.

Reduced Variability with Trend Analytics:

Through real-time trend analytis, pareto chart, and alarming the site was able to reduce variation on ClO2 gpl variation by 40%.

Other Beneficial Outcomes of PARCview

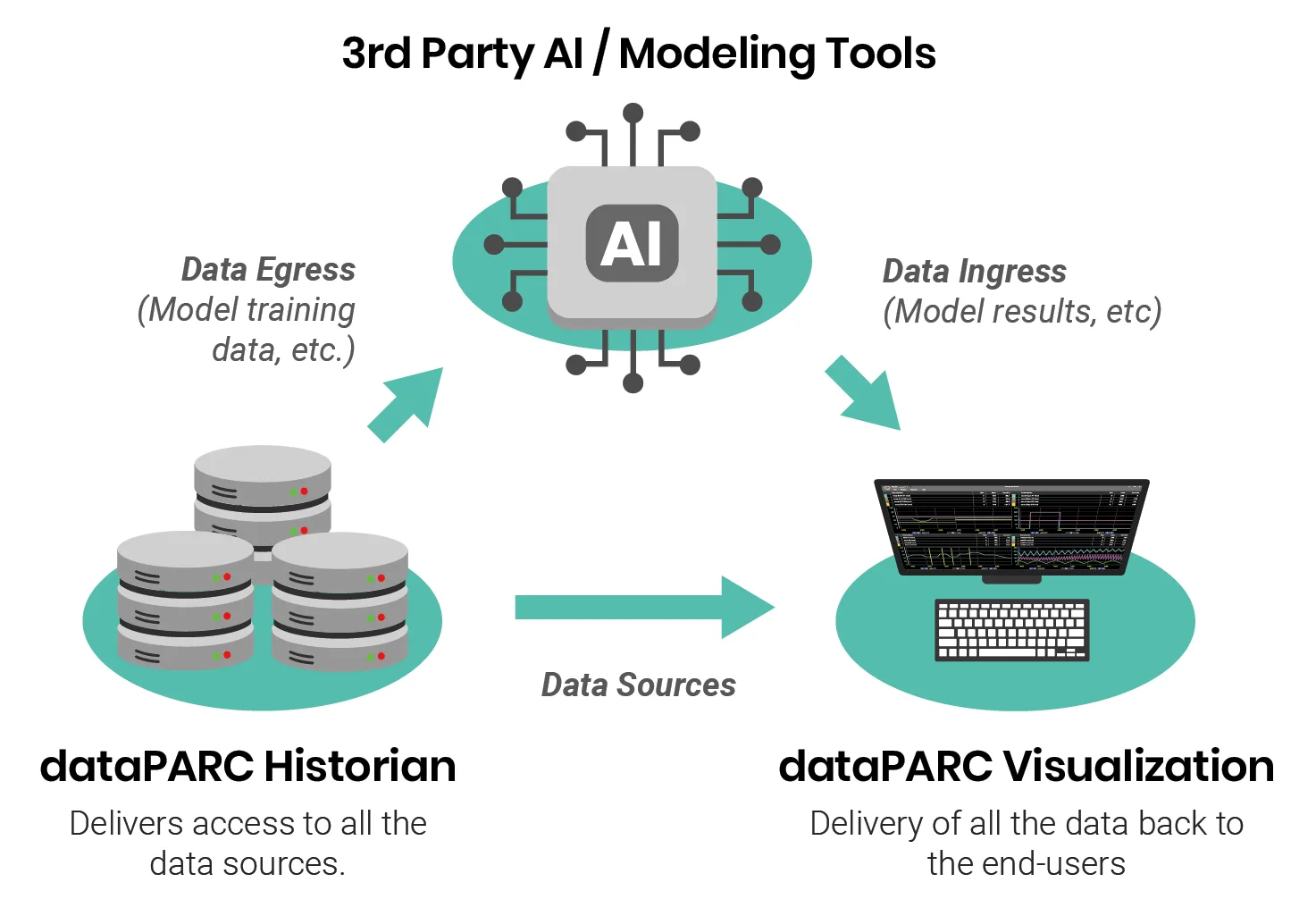

Kuantum reshaped its operations by pairing dataPARC’s real-time data infrastructure with AI and Advanced Process Control (APC) tools. But before AI could make an impact, the groundwork had to be laid. Kuantum first focused on centralizing and structuring its plant data, bringing 35,000+ tags and over a dozen sources into one integrated platform. This foundation was critical.

With dataPARC in place, the team could move beyond basic analysis and use that unified data environment as an AI enabler. The system now feeds real-time process data to modeling tools like MACS, etc. and delivers model results back to operators, directly within their decision-making workflows.

This seamless loop of real-time monitoring, model-driven optimization, and human insight has powered major performance gains, including case studies in pulp quality and boiler efficiency. None of it would have been possible without first getting the data right.

Major Achievements: Pulp Quality Improvements:

By adopting AI-driven model predictive control MACS, Kuantum achieved impressive gains in pulp production quality. They reduced pulp brightness variability by 70%. Real-time monitoring, automated reports, and AI adjustments ensure consistent quality across production.

Boiler Efficiency Enhancements:

Optimization didn’t stop with pulp production. Kuantum applied MACS and AI technology to improve boiler operations as well. They saw faster control response to operational changes. Oxygen level and steam header pressure tightening allowed boiler efficiency improvement.

Cultural Shift: Data-Driven Decision Making:

With real-time insights and predictive control, Kuantum is building a future-ready operational culture. They want to empower their workforce and improve their skill levels and technical expertise.

They aimed to shift meetings from traditional reporting to active working sessions and have proactive operations where teams identify trends and prevent issues before they impact production quality.

The Road Ahead: Expanding AI Applications

Kuantum Paper does not plan on slowing down anytime soon, they are looking at way to continue to expand AI into their facility, especially with the strong data foundation they have built. The site in one stage or another from implantation through sustainability in six different departments throughout the plant. This is a mill wide effort and culture shift.

Conclusion

The implementation of PARCview and dataPARC Historian has proven to be a transformative step for Kuantum Paper. Real-time monitoring, streamlined data consolidation, and the integration of additional data sources have significantly improved operational efficiency. With future expansions and optimizations planned, PARCview continues to play a pivotal role in enhancing the company’s ability to deliver reliable and efficient utility services to its customers.

More Success Stories

Drax Biomass

See how Drax Biomass developed an organization-wide data management strategy for their pellet production operations.

Energy Transfer

See how Energy Transfer underwent a complete digital transformation, saving them time, money, and enabling better decision-making.

Western Plains Energy

See how Western Plains Energy developed data-driven insights and improved product quality and process efficiency at their ethanol plant.

Kuantum Papers LTD.

Download the case study to see how dataPARC helped Kuantum Papers LTD. optimize operations, utilizing real-time data monitoring and streamlined consolidation processes.