SPC / SQC

Easily implement online SPC/SQC utilizing dataPARC’s integrated limit management tools and alarm/event engine.

Determine Capabilities

Determine if your process is stable and capable of producing products within your specification limits.

Analysis Of Any Data Source

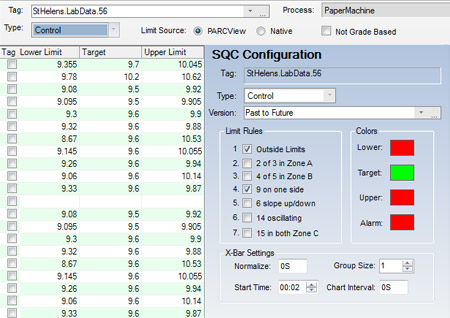

Apply PARCview’s SPC/SQC analysis to tags from any data source available to dataPARC. Build control charts (x-bar, range, standard deviation, etc.) from existing sources or PARCview formulas. Define simple min/max limits, choose from Western Electric Rules or custom logic. Limits can be managed natively in dataPARC or imported from a 3rd party database.

Flexible Rule Definitions

Custom limits to built in Western Electric Rules or custom logic can be used to identify out-of-control points. User-defined color coding for rule violations provides operators with real-time feedback by highlighting special causes in Trend, Centerline, and Manual Data Entry displays. The display tool shows which rule was violated and allows users to assign a cause.

Grade-based Limits

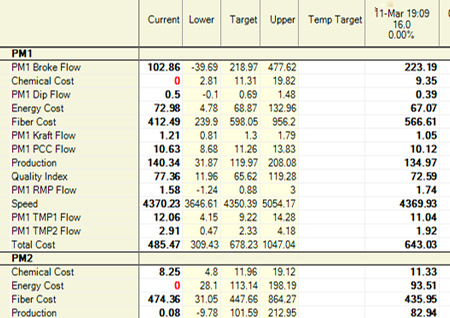

Create control and specification limits for each product category. PARCview will automatically display limits based on the defined criteria. When a new grade or product run begins, PARCview displays switch to the appropriate limits. Full support for limit versioning allows historical comparisons and all displays will use the limits that were in effect during the time period being evaluated.

Centerline and Histogram Integration

In addition to Trends, PARCview’s Centerlines and Histogram charts provide a platform for SPC/SQC analysis and calculation of Cpk by product or grade. Both operators and engineers can take advantage of Centerlines with SPC/SQC limits enabled to work on centering their process for peak performance.

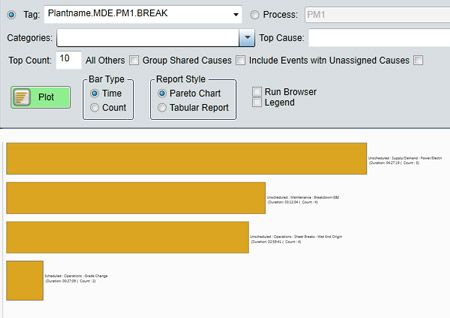

Root-Cause Analysis

Deliver additional value to SPC/SQC initiatives through root-cause analysis. PARCview makes it easy with off the shelf capability to create events, capture reason assignment and deliver analysis of all SPC/SQC rule violations.

Want To Learn More?

Click the links below to recieve a FREE PDF on the solutions dataPARC has to offer for SPC/SQC.