Downtime Tracking Software for Manufacturing

Immediately Track & Analyze Downtime Events for Faster Recovery

Monitor unplanned downtime as it happens. Get alerts in real-time, log accurate event data, and generate actionable reports to reduce disruptions, support OEE goals, and improve plant performance.

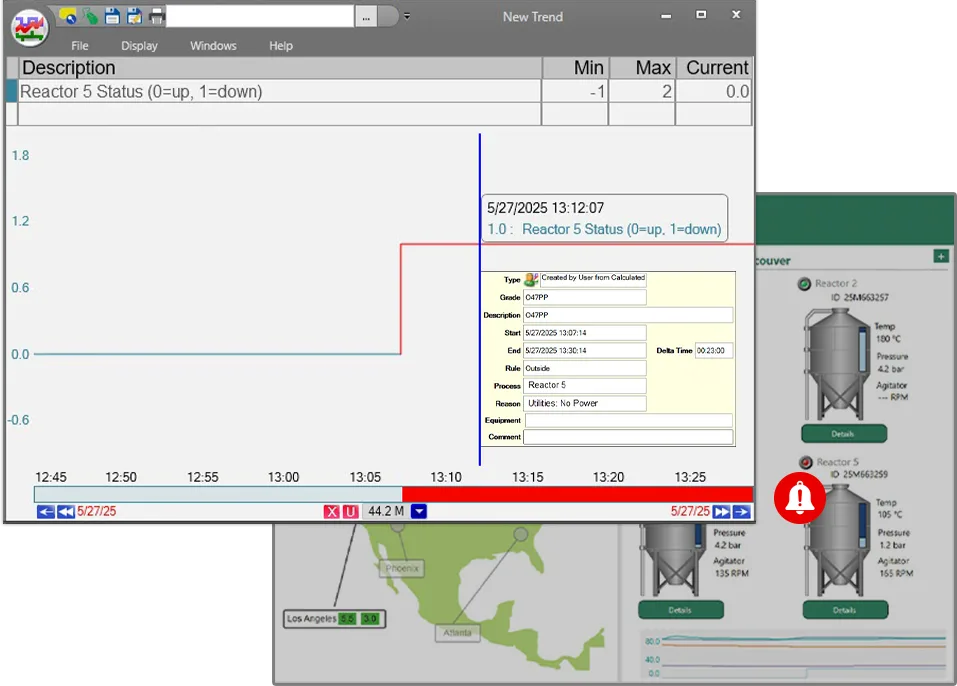

Respond Quickly with Real-Time Downtime Alerts

Set up real-time alarms to instantly detect and respond to downtime events, ensuring minimal disruption to your operations.

- Customize alarm thresholds to match your specific operational needs.

- Receive notifications via email or SMS alerts.

- Configure alarms for various downtime scenarios, including equipment failure, process slow back, interruptions, and quality issues.

- Integrate alarms with other systems for a seamless operational workflow.

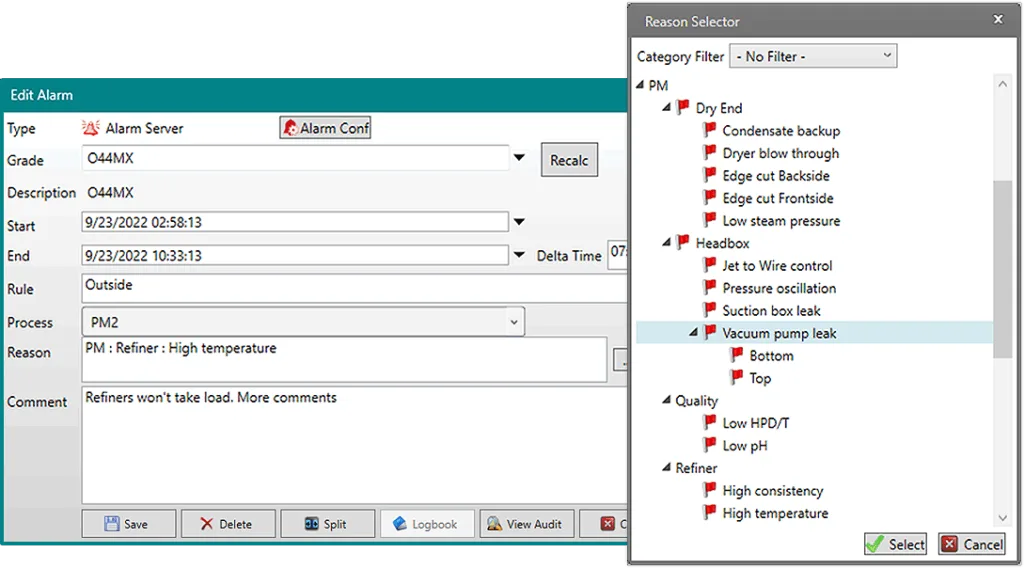

Track Not Only When Downtime Happens But Why

Efficiently track and document downtime by assigning detailed reasons and comments, providing comprehensive insights into every event.

- Use a customizable, preassigned reason tree to standardize downtime categorization.

- Add detailed comments to each downtime event for better context and understanding.

- Assign downtime reasons in real-time to ensure accurate data capture.

- Include additional data as evidence such as inventory levels and test results to support your analysis.

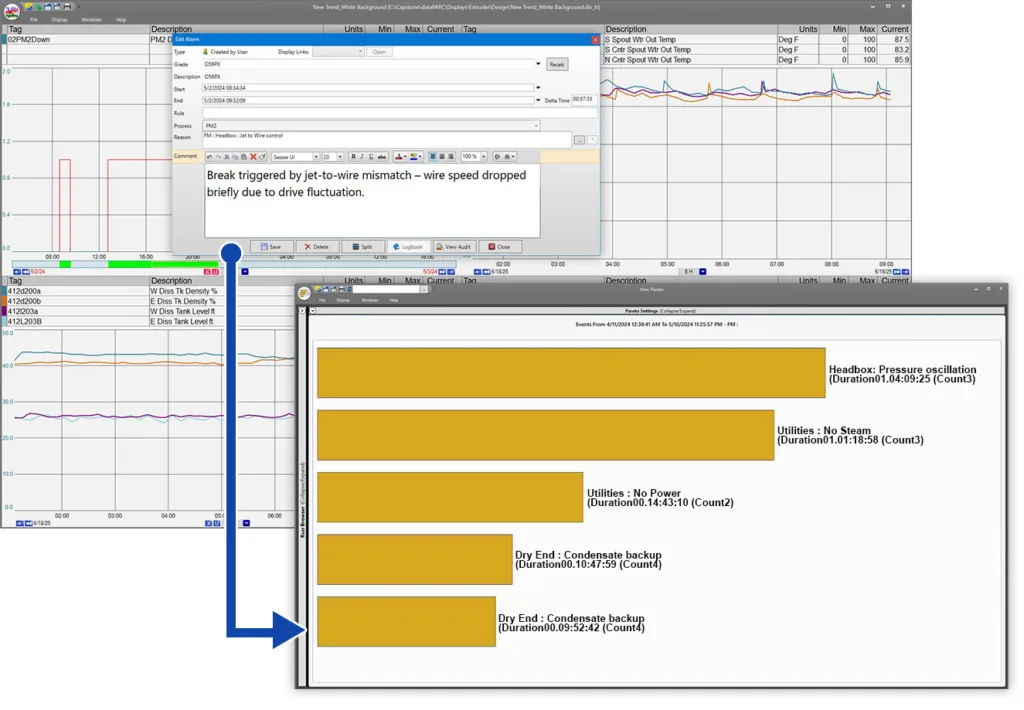

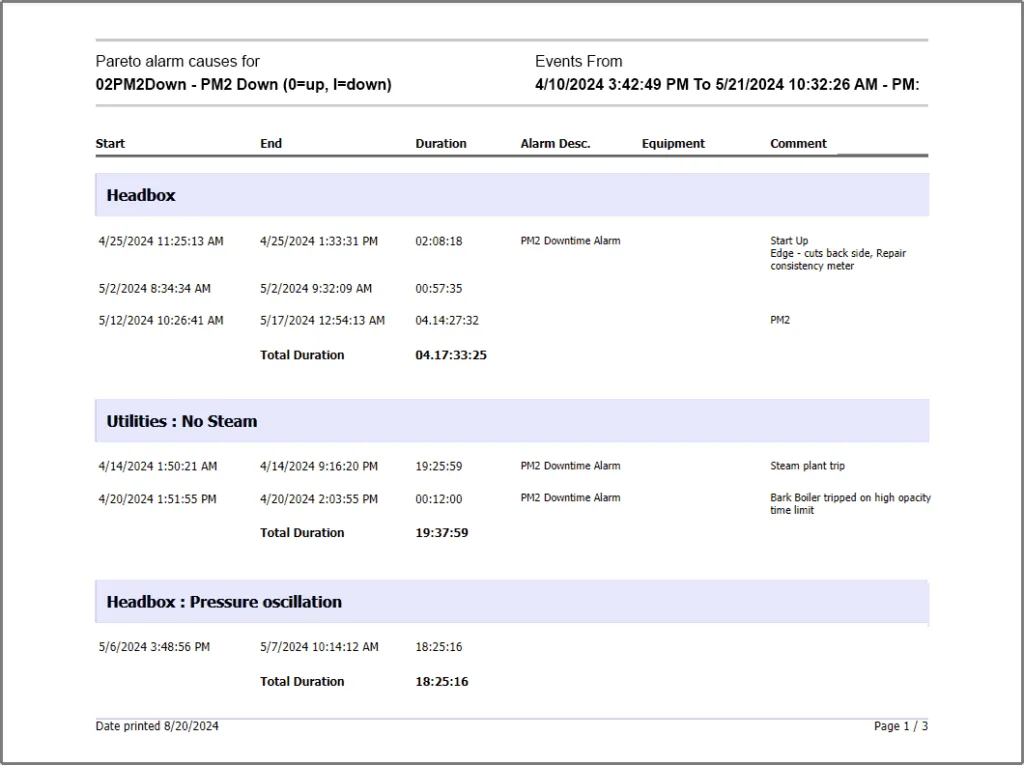

Identify Root Causes with Pareto Analysis

Leverage powerful Pareto charts and detailed reports to identify root causes and eliminate the primary sources of downtime in your operations.

- Generate Pareto charts to highlight the most significant contributors to downtime.

- Use other tag data or manual entries as evidence for additional analysis.

- Create detailed reports that summarize downtime reasons, duration, and impact.

- Analyze trends and patterns to identify areas for improvement.

- Implement targeted corrective actions based on data-driven insights to reduce future downtime.

Automate Downtime Reports for Actionable Insights

Streamline your analysis and review process with scheduled and alarm-triggered reports, capturing critical data and insights on every downtime event.

- Automatically generate reports based on predefined schedules to capture and review downtime events systematically.

- Initiate reports instantly when specific alarms are triggered, ensuring immediate attention to critical downtime issues.

- Tailor reports to meet specific needs, focusing on key performance indicators and detailed event logs.

- Incorporate additional data such as inventory levels and test results to enrich the analysis and support conclusions.

Featured Case Study

Kapstone Paper

The global containerboard market is highly competitive, making process optimization essential to a paper mill’s survival. KapStone’s technical team turned to dataPARC to help them centerline their process, identify golden runs, and reduce costs.

Providing Customers with Downtime Tracking Solutions for 25+ Years

We use dataPARC to troubleshoot operations and drive feedstock costs by 200%

Caleb W

Control Systems Engineer

(dataPARC is helping us) Visualize data, track downtime and production quality

Jason N.

ITOT Manager

The alarm/alert system is also a great way to keep up to date on how things are running when you aren’t in front of your computer.

Nicolas G.

Production Shift Supervisor

The World’s Largest Manufacturers Depend on dataPARC

Beyond Downtime Tracking Software

Tackle common manufacturing challenges with PARCview’s out-of-the box functionality.

OEE Tracking

Analyze production loss from unplanned downtime, poor quality, and performance issues.

Root Cause Analysis

Uncover underlying issues with dashboards and trends to resolve recurring problems systematically.

Additional Features

dataPARC is a flexible industrial analytics toolkit built upon the promise of easy data acquisition & integration. dataPARC’s core building blocks can be used to build any applications to meet your needs.

Dynamic Alarms & Notifications

Use dataPARC’s rule-based alarm engine to build smart alarm definitions that reliably detect compliance events, including data loss, real time, and aggregate exceedance of regulation limits. Forward alarm event data to PARCview’s Logbook, and send notifications via email or SMS.

Custom Report Builder

PARCview’s highly configurable scripting and scheduling application can schedule and deliver recurring reports or other key data to management and other decision-makers. Create event-triggered reports, dashboard report delivery, & scheduled reports.

Excel Add-In

Designed to automate common or tedious Excel tasks and make it easy to build reusable reports, PARCxla enables users to spend more time making important decisions and less time wrestling with data.

Manual Data Entry

PARCgraphics Designer’s form-based MDE tools offer a platform for constructing custom data entry screens. Enter data against a record from anywhere within the dataPARC environment, across multiple MDE pages, PCs, and locations.

Batch Analysis Tools

Arrange multiple batches by product into a comparison or consecutive view. Search for historical batches based on identifying information, such as batch ID or product label. Determine variability at any point in the batch using Run Trend analysis.

Control Charts

Build control charts (x-bar, range, standard deviation, etc.) from existing sources or PARCview formulas. Define simple min/max limits, choose from Western Electric Rules or custom logic. Limits can be managed natively in dataPARC or imported from a 3rd party database.

Download Our Overview Datasheet

Click the link below to receive a FREE overview on the benefits of using dataPARC to transform critical data into visual information for timely decision-making.