If you’ve been looking for an eDNA replacement for a while for real-time and historical insights, this article shows how to replace it without losing context. We cover must-have features, common pitfalls with SaaS moves, and why dataPARC’s historian, visualization, and tag-based licensing make it a strong successor. You will also see a clear migration path that recreates your dashboards and keeps long-term trends intact.

Eliminate Lag with a High-Performance Data Platform Built for Scale

Why Manufacturers Are Moving Beyond eDNA

eDNA is an enterprise real-time and historical data management platform designed to collect, store, display, analyze, and report on operational and asset health information. It has helped manufacturers transform raw data into actionable insights and served as a central system for visibility across process operations.

However, many facilities using eDNA have decided to move away from it. AVEVA itself has an eDNA to PI Migration path in place. Whether driven by changes in vendor support, evolving licensing models, or the need for more modern analytics capabilities, organizations are evaluating their options for maintaining continuity in visibility, reporting, and analytics.

Some are exploring alternatives like the PI System or other SaaS-based solutions, but these come with new considerations, including different licensing structures, potential cloud migrations, and varying levels of data control. As a result, many manufacturers are seeking a modern replacement that maintains the flexibility, accessibility, and performance they’ve relied on while providing greater control over how their data is used and shared.

Check out dataPARC’s real-time process data analytics tools & see how better data can lead to better decisions.

Evaluating Your Options: What Matters Most in an eDNA Replacement

When transitioning from eDNA, the goal isn’t just to find a replacement; it’s to find a platform that improves on what worked while removing limitations. The right solution should enhance your operational capabilities, not just replicate existing functionality.

For manufacturers coming from eDNA, consider solutions that provide:

Core Technical Requirements:

- A full historian + visualization platform — not just dashboards or reports, but a complete time-series data management system with sub-second query response for multi-year datasets.

- Open connectivity standards — OPC DA/UA, and SQL support to eliminate vendor lock-in and enable integration with both legacy systems and modern IoT devices.

- Data migration capabilities — the ability to preserve historical context and recreate existing displays without starting from scratch.

- Scalable architecture — support for 10k, 50k, 100k+ tags with consistent performance across distributed deployments.

Operational Accessibility:

- Flexible licensing models — options that don’t restrict data access based on user count, enabling cross-functional collaboration. It’s your data, you should have access to it.

- Multi-role accessibility — allowing everyone from quality and lab teams to operations and IT to access the same data environment.

- User-friendly configuration — intuitive interfaces that don’t require specialized IT support for routine modifications.

Analytics and Visualization:

- Configurable dashboards and trends — gauges, KPIs, navigation buttons, and multi-trend views that operators and engineers can build and modify.

- Contextual analysis tools — the ability to manipulate trends, define production runs, and calculate derived parameters directly within the platform.

- Integration with business systems — connecting process data with ERP, MES, LIMS, and other enterprise systems for faster, more informed decision-making.

While PI System and PI Vision offer robust capabilities, their transition toward SaaS models and user-based licensing structures may not align with every organization’s data strategy or budget constraints. The best eDNA alternative should give you complete access to your data, intuitive tools, and a deployment model that supports your operational requirements.

The Best eDNA Replacement: dataPARC

For manufacturers seeking a reliable and future-ready alternative to eDNA, dataPARC offers a complete data historian and visualization platform that delivers the flexibility, accessibility, and performance modern operations require.

Complete Data Ecosystem

dataPARC provides a complete real-time and historical data management system that combines efficient time-series storage with high-performance visualization and analysis tools. The platform uses a trend-optimized data structure that significantly reduces the number of stored data points without sacrificing accuracy or visual quality. This approach maintains the true shape of process trends while minimizing database size, resulting in major performance gains, especially when viewing large time ranges or multi-tag comparisons.

This unique PARCview trend is independent of the graphics display and is created and saved on the fly without having to open a dashboard. Saving the user time and clicks.

To further enhance speed, dataPARC automatically creates summarized archives for long-term data and event-based calculations, such as production runs or product grades. When engineers trend data over extended periods, the system intelligently retrieves this optimized data to deliver rapid response times, even across years of history.

In practical terms, this architecture allows users to access and analyze multi-year datasets within seconds rather than minutes, all while preserving the detail and fidelity needed for precise engineering and operational insight.

Unrestricted Data Access

Tag-based licensing ensures unrestricted data access across all roles without per-user fees. Anyone across your site, operators, engineers, quality teams, IT, or scheduling, can view and analyze data. It’s your data, and your team should have access when they need it. This approach makes collaboration easier and ensures everyone is working from the same information, supporting consistent decision-making from the control room to management.

Familiar Interface, Enhanced Capabilities

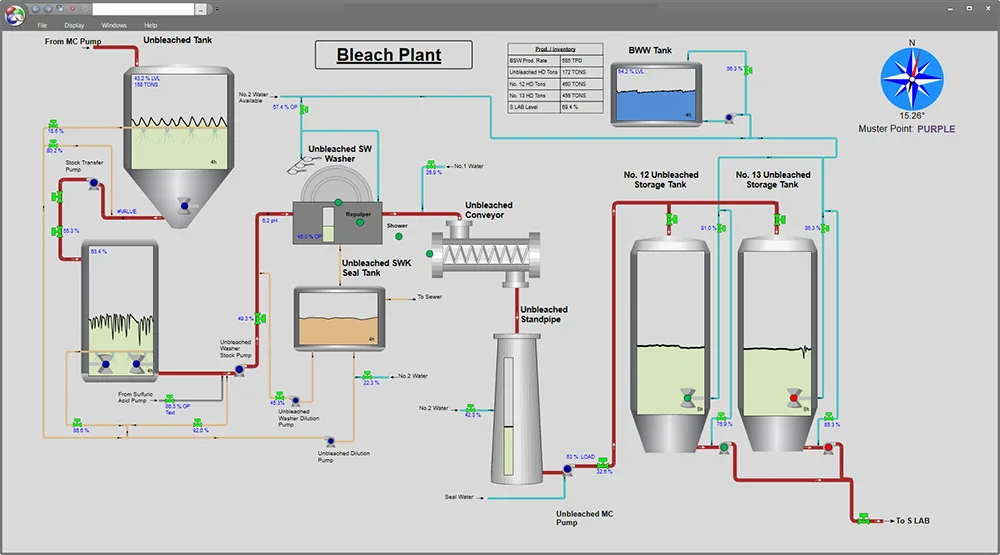

Like eDNA, dataPARC supports configurable dashboards with gauges, KPIs, and real-time values. Users can build interactive screens that display live process data, navigate between dashboards, and click on any value to instantly open a trend for deeper analysis. The platform goes beyond basic visualization by enabling:

Custom process dashboards can be created in PARCview to assist with production monitoring and analysis.

- Multivariate analysis — Apply PCA and PLS techniques to identify which process variables correlate most strongly with quality deviations.

- Statistical process control — Built-in SPC capabilities for real-time monitoring and historical capability analysis.

- Contextual collaboration — The Logbook feature captures crew notes and shift details, connecting human insight with process data for more complete operational records.

How the Migration Process Works

Switching from eDNA to dataPARC is designed to protect your existing data and minimize downtime so you can keep your operations running without interruption.

1. Assessment and Planning

The migration begins with a full system review to identify which dashboards, tags, and trends are most critical to operations. This stage includes evaluating data retention requirements, archive structures, and any custom calculations or integrations that must be replicated. Teams also determine hardware and infrastructure needs based on tag count and expected data volume to ensure that the new system performs reliably and scales effectively.

2. Data Source Integration

Once the plan is in place, the next step is connecting dataPARC to existing data sources. This may include replacing historians, or integrating with current historians, control systems such as PLCs or DCS, and lab databases. Standard connections like OPC DA, OPC UA, or SQL are configured as needed. Data quality, timestamp alignment, and signal consistency are validated to ensure that data from all systems is accurate and synchronized.

Data integration establishes a single source of truth for all your manufacturing data.

3. Display and Workflow Recreation

Existing eDNA displays are then rebuilt within dataPARC to preserve familiar layouts and user workflows. Engineers configure real-time gauges, multi-trends, KPIs, and interactive dashboards that mirror what operators are used to. Custom calculations, derived tags, and department-specific views are reestablished, while user roles and permissions are configured to maintain secure and appropriate access across teams.

4. Historical Data Continuity

Maintaining data continuity is a key part of the migration. Historical archives are integrated into dataPARC so users can continue viewing complete trends without data gaps. System performance is also tested by running representative queries over long time spans to confirm that data is retrievable quickly and accurately.

5. Validation and Training

Before the system goes live, users validate that performance meets operational needs under typical and peak query conditions. Training sessions are provided to help engineers, operators, and analysts become comfortable navigating the system. The intuitive interface makes adoption straightforward, while dataPARC’s team assists with any site-specific configurations or questions.

Why dataPARC is the Right Choice

dataPARC stands out as a strong eDNA alternative because it combines technical performance with ease of use on a single platform. Designed by engineers for engineers, the interface is intuitive and supports fast troubleshooting, trending, and analysis without requiring specialized IT assistance for day-to-day configuration or maintenance.

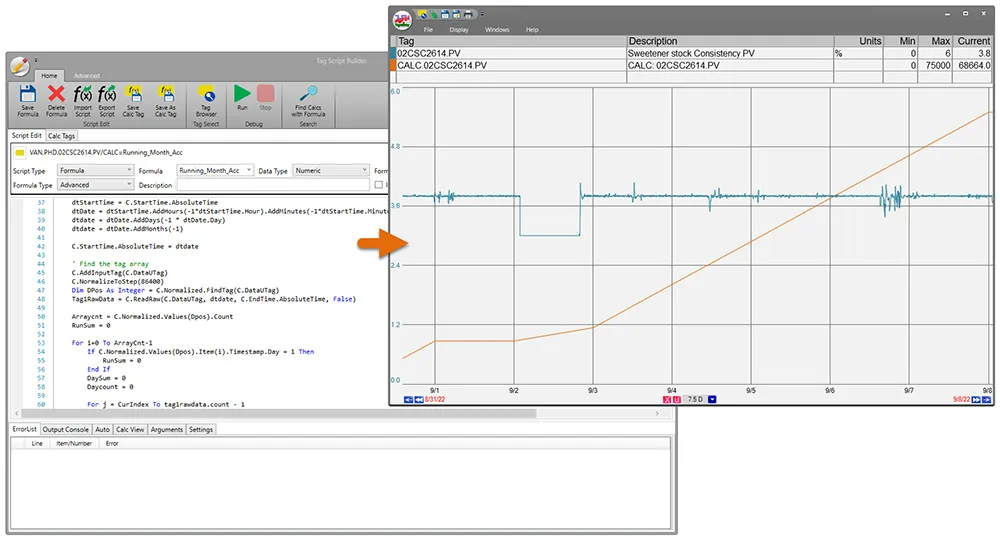

Users can create calculations and trend them within PARCview without IT assistance.

The platform delivers a complete data ecosystem that includes a high-performance historian capable of managing a growing tag count while maintaining consistent query response. It also incorporates powerful visualization tools, advanced analytics, and collaboration capabilities such as integrated logbooks for tracking operator and engineer notes.

dataPARC’s tag-based licensing model ensures open access across the organization, allowing operators, engineers, and managers to all work from the same data without user-based restrictions.

Connectivity is another key strength. The system can integrate virtually any data source through standard industrial and IT protocols, including OPC DA, OPC UA, gRPC, SQL, and REST APIs. This open architecture enables a unified and consistent view of process information across the enterprise.

Built with scalability in mind, dataPARC supports everything from single-site installations to enterprise-wide deployments while maintaining years of high-resolution historical data. It has been proven across multiple industries, including pulp and paper, chemicals, power generation, oil and gas, and food and beverage, where it supports complex multi-site operations and large tag counts with exceptional performance.

For companies moving away from eDNA, dataPARC provides a smooth transition and a solid foundation for future growth in real-time and historical data management.

Final Thoughts: Choose a Platform That Puts You in Control of Your Data

Evaluating alternatives to eDNA is an opportunity to adopt a platform built for modern analytics requirements, one that preserves your institutional knowledge while enabling advanced capabilities like predictive modeling, statistical process control, and cross-plant benchmarking.

When selecting a replacement, it’s important to choose a platform that not only replicates eDNA’s capabilities but also improves on them. dataPARC provides a proven migration process, open connectivity standards, and flexible licensing that gives every user access to the information they need without artificial restrictions.

Your process data is one of your most valuable assets. With dataPARC, you maintain control of it while gaining the performance, scalability, and visualization tools needed to make faster, more informed decisions. The platform grows with your organization, supporting everything from single-plant deployments to enterprise-wide data strategies that span multiple facilities and connect operational data with business intelligence systems.

An eDNA replacement doesn’t mean starting over; it means building on what worked while moving to a platform designed for the next generation of manufacturing analytics.

FAQ About Migrating from eDNA

- What happens to our historical eDNA data?

Historical data can be integrated into dataPARC. The platform can connect to existing data sources and maintain trend continuity, or data can be backfilled to the dataPARC Historian. - How long does migration typically take?

Timeline varies based on the number of tags, complexity of custom displays, and extent of historical data integration. A typical single-site migration ranges from 8-24 weeks. - Can we run dataPARC and eDNA in parallel during transition?

Yes, parallel operation is common during migration. This allows operators to maintain familiarity with existing systems while validating dataPARC performance and building confidence with the new platform. - What hardware and infrastructure is required?

dataPARC can run on standard server hardware, with requirements scaling based on tag count and query load. For a full list of hardware requirements, see our dataPARC Hardware Guide. - Do we need IT support for ongoing configuration?

While IT involvement is helpful for initial setup and system integration, dataPARC’s engineer-accessible interface allows process and automation engineers to handle routine tasks like building dashboards and creating derived calculations without requiring IT tickets.

Building The Smart Factory

A Guide to Technology and Software in Manufacturing for a Data-Drive Plant