Industrial data historians have become essential infrastructure for modern manufacturing, serving as the foundation for operational intelligence, continuous improvement, and regulatory compliance. These specialized systems capture, store, and provide access to the process data that drives data-driven decision making across your organization. Whether you’re evaluating your first historian or considering an upgrade from an aging system, understanding what separates good from great is essential. This post breaks down the critical capabilities every industrial data historian should possess and how to evaluate whether a solution truly delivers on these fundamentals. By the end, you’ll have a clear framework for making an informed decision that will serve your operation for years to come.

Fast, scalable data historian at a fraction of the cost. Check out the dataPARC Historian.

In modern manufacturing and process industries, data is the lifeblood of operational excellence. Every sensor reading, every process variable, and every equipment status indicator tells a story about plant performance, efficiency, and quality. But capturing this data is only half the battle. Storing it reliably, accessing it quickly, and turning it into actionable insights requires specialized technology: an industrial data historian.

Not all industrial data historians are created equal. Some excel at high-speed data collection but struggle with user accessibility. Others couple with beautiful visualizations but lack the robust integration capabilities needed in complex industrial environments. The difference between a mediocre historian and an excellent one can mean the gap between reactive troubleshooting and proactive optimization, between gut-feel decisions and data-driven certainty.

High-Performance Data Collection and Storage

The foundation of any industrial data historian is its ability to collect and store process data efficiently and reliably. In industrial environments where processes can change in milliseconds, missing even a single data point can mean overlooking a critical event that led to quality issues, equipment failure, or safety incidents.

Sub-second data capture

Sub-second data capture matches your process dynamics. Whether you need data every 100 milliseconds for high-speed packaging or every second for chemical reactions, your historian must keep pace without dropping samples or creating bottlenecks.

Scalability

Scalability ensures growth without performance degradation. Your historian should handle expansion from hundreds to tens of thousands of tags seamlessly, ideally offering distributed architectures for enterprise-wide deployments.

Without these capabilities, you’re building your data strategy on a shaky foundation. The right industrial data historian makes collection and storage invisible, reliable, and cost-effective.

Reliable Data Integrity and Security

Data you can’t trust is worse than no data at all. An industrial data historian must guarantee accurate storage, protect against unauthorized access, and maintain complete records.

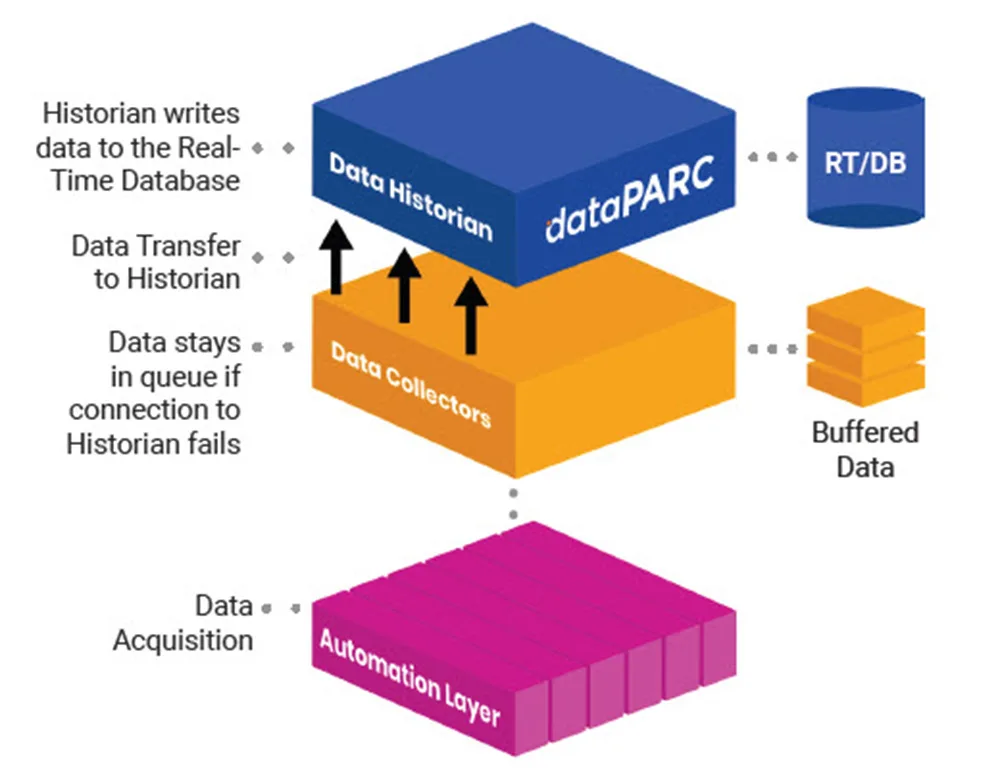

Store-and-forward capabilities

Store- and-forward prevents data loss during network disruptions. A robust historian buffers data locally when connections drop, then automatically forwards it once restored. Your historical record stays complete. Your compliance obligations are met.

How the dataPARC dataPARC historian store-and-forward technology works, ensuring no data is lost to network distuption.

Audit trails

Audit trails create accountability. In regulated industries, logging who accessed data, modified configurations, or changed settings is essential. Regulators demand proof. Audit trails provide evidence. Compliance becomes achievable.

Cybersecurity features

Security protects your infrastructure. Strong authentication, role-based access controls, encrypted communications, and secure APIs keep your process data confidential and your plant protected.

Data integrity and security aren’t glamorous, but they’re foundational. An industrial data historian that compromises here puts your operations and competitive advantage at risk.

Seamless Integration with Plant Systems

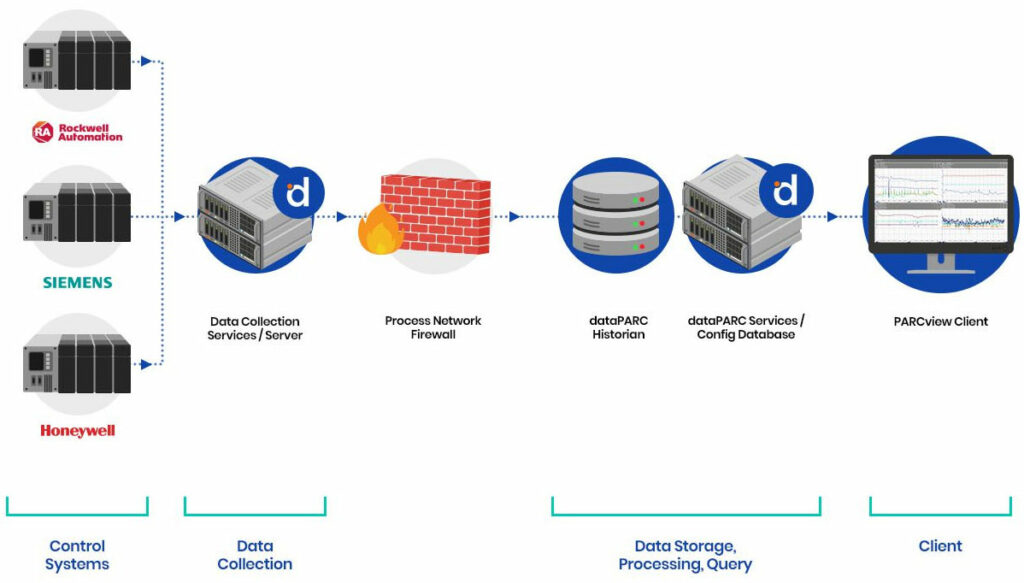

A process data historian must connect to the diverse ecosystem of automation systems, databases, and applications that run your facility. Easier integrations mean faster deployment and quicker value extraction.

This is an example of standard implementation of the dataPARC historian as it collects data fromm all the automation systems and control systems in your plant.

OPC and OPC UA support

This provides universal industrial connectivity. A capable historian connects to virtually any control system, SCADA platform, or industrial device through these de facto standards. OPC provides interoperability. OPC UA adds security.

Native connectivity to PLCs, DCS, and SCADA

Native connectivity eliminates middleware complexity. Direct drivers for Allen-Bradley, Siemens, Honeywell, Emerson, and others often provide better performance and simplified configuration. Your data flows faster. Your architecture stays simpler.

Database integration

Database integration bridges operational and business systems. Manufacturing execution systems (MES), ERP platforms, and laboratory information systems (LIMS) all need historian data. Bi-directional connectivity makes these workflows possible, letting process data inform business decisions while business context enriches process analysis.

Integration challenges kill projects. Comprehensive, proven connectivity accelerates deployment and ensures your data infrastructure evolves with your technology landscape.

Powerful Data Retrieval and Analysis

Collecting data is pointless if you can’t retrieve it quickly when you need it. An industrial data historian must make data access fast, flexible, and frustration-free.

Fast query performance

This separates excellent historians from mediocre ones. When troubleshooting a process upset, engineers need to pull up weeks of multi-variable trends in seconds, not minutes. Slow queries kill productivity and discourage data-driven decision making. This can be part of your workflow productivity index when reviewing a historian. You want to make sure your questions get answered quickly. Your analysis stays fluid. Your team stays engaged.

Flexible aggregation

Flexible aggregation adapts data to your analytical needs. Raw data at sub-second resolution is invaluable for root cause analysis, but reviewing a month of high-frequency data is overwhelming. Quality historians calculate meaningful aggregates: hourly averages, daily minimums and maximums, time-weighted values that account for how long a process stayed in each state. The data presentation matches your question. The insights emerge clearly. The analysis stays relevant.

API access

API access future-proofs your investment. Python scripts for machine learning, custom web dashboards, mobile applications, and integration with third-party analytics platforms all require programmatic access to your historian. REST APIs, SQL interfaces, and language-specific SDKs open possibilities beyond the historian’s native interface. Your innovation accelerates, customization expands, and your competitive advantage grows.

Intuitive Visualization and Trending

The best industrial data historian in the world is worthless if your team can’t easily visualize and interpret the data it contains. Usability determines adoption, and adoption determines value.

User-friendly interfaces

User-friendly interfaces put power in everyone’s hands. Operators shouldn’t need IT support to pull up a trend. Engineers shouldn’t need repeated training courses to compare process variables. A well-designed historian offers intuitive navigation, drag-and-drop trending, and logical organization that matches how people think about their processes. The team gets immediate access, and insights begin to arrive, and your ROI multiplies.

Multi-variable trending

Multi-variable trending reveals relationships that single-variable views miss. Process interactions drive most operational challenges. Temperature affects viscosity. Pressure influences flow rate. Feed composition impacts product quality. Plotting these variables together on synchronized time axes exposes correlations, lead-lag relationships, and cause-and-effect patterns. The connections become visible. The root causes emerge clearly. The solutions present themselves.

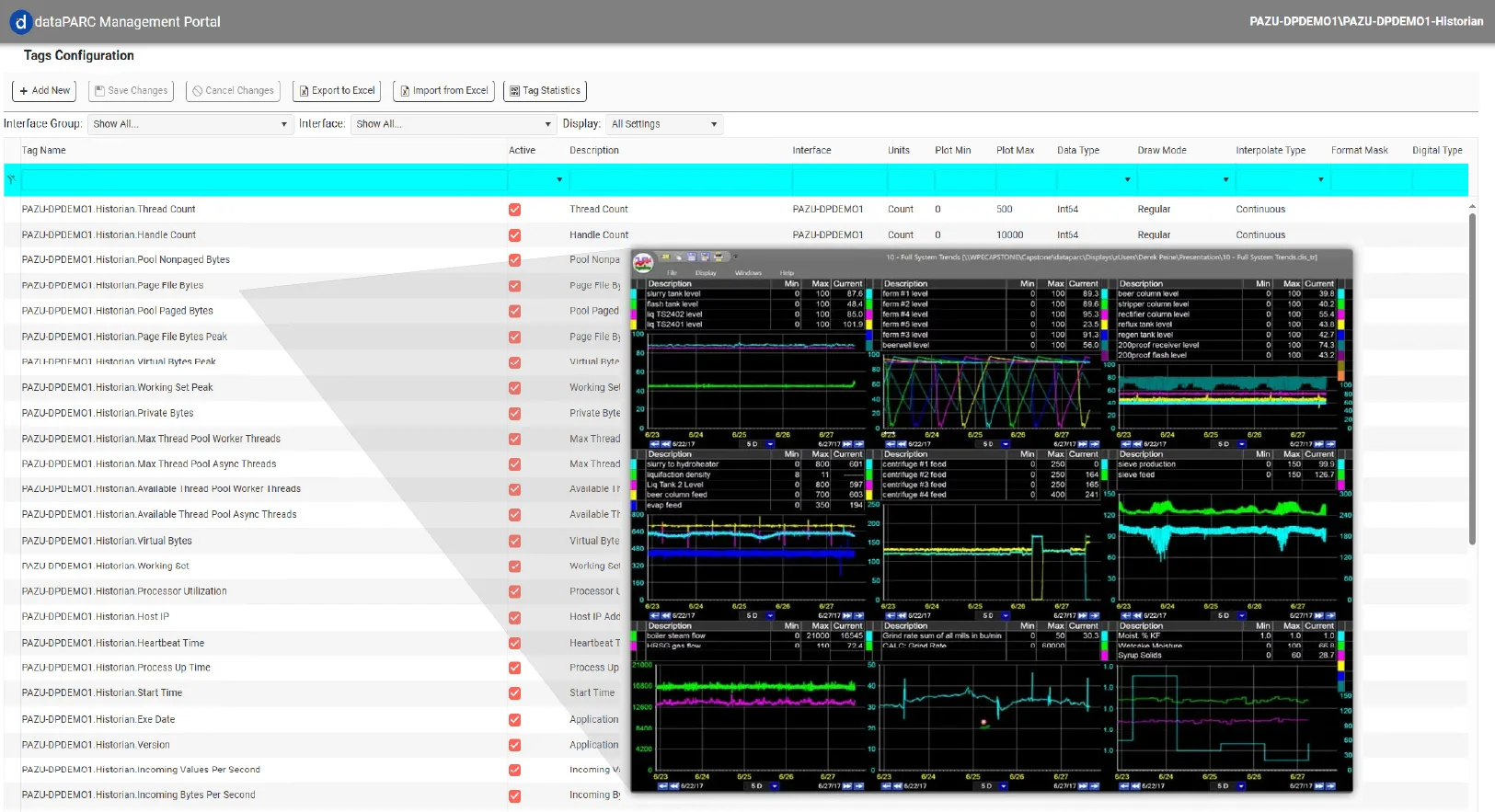

Multi-trends are a unique feature to PARCview where users do not have to open a dashboard to save multiple trends on one screen. It is all done within the trend window. Fast and intuitive.

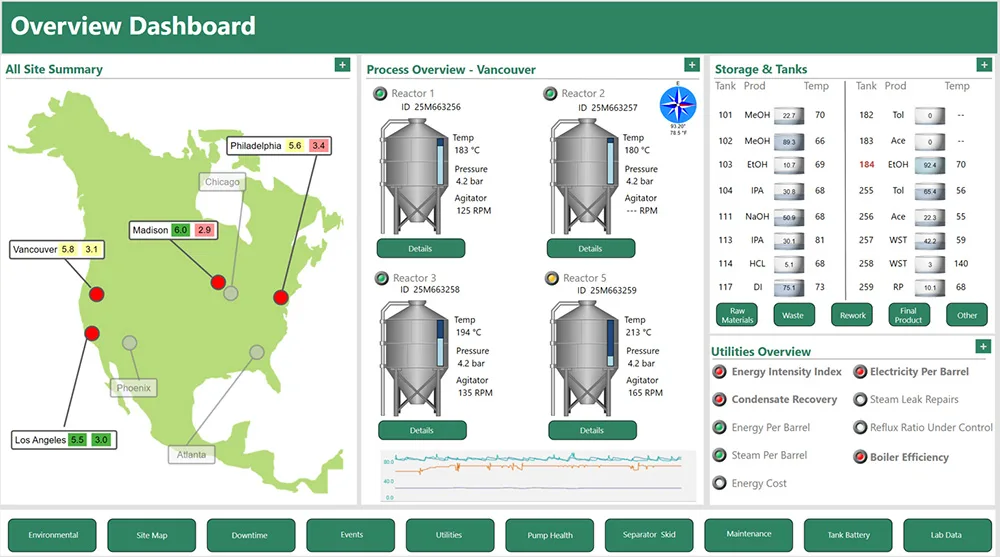

Customizable dashboards

Dashboards deliver the right information to the right people. Plant managers need high-level KPIs. Process engineers need detailed variable trends. Maintenance teams need equipment health indicators. Role-based dashboards present relevant data without clutter or confusion. Each role sees what matters, user stays focused, and decision get better support.

Mobile access

Mobile access extends your historian beyond the control room. Troubleshooting happens everywhere: on the plant floor, in management meetings, and at home during after-hours calls. Mobile-optimized interfaces or dedicated apps let stakeholders view trends, check current values, and make informed decisions from any device.

Proven Track Record and Ease of Maintenance

An industrial data historian is a long-term investment that will store decades of operational knowledge, but even the most capable system becomes a liability if it requires constant IT attention or specialized expertise to keep running. Choosing a solution that balances operational simplicity with proven staying power protects your investment and ensures your data remains accessible as technology evolves.

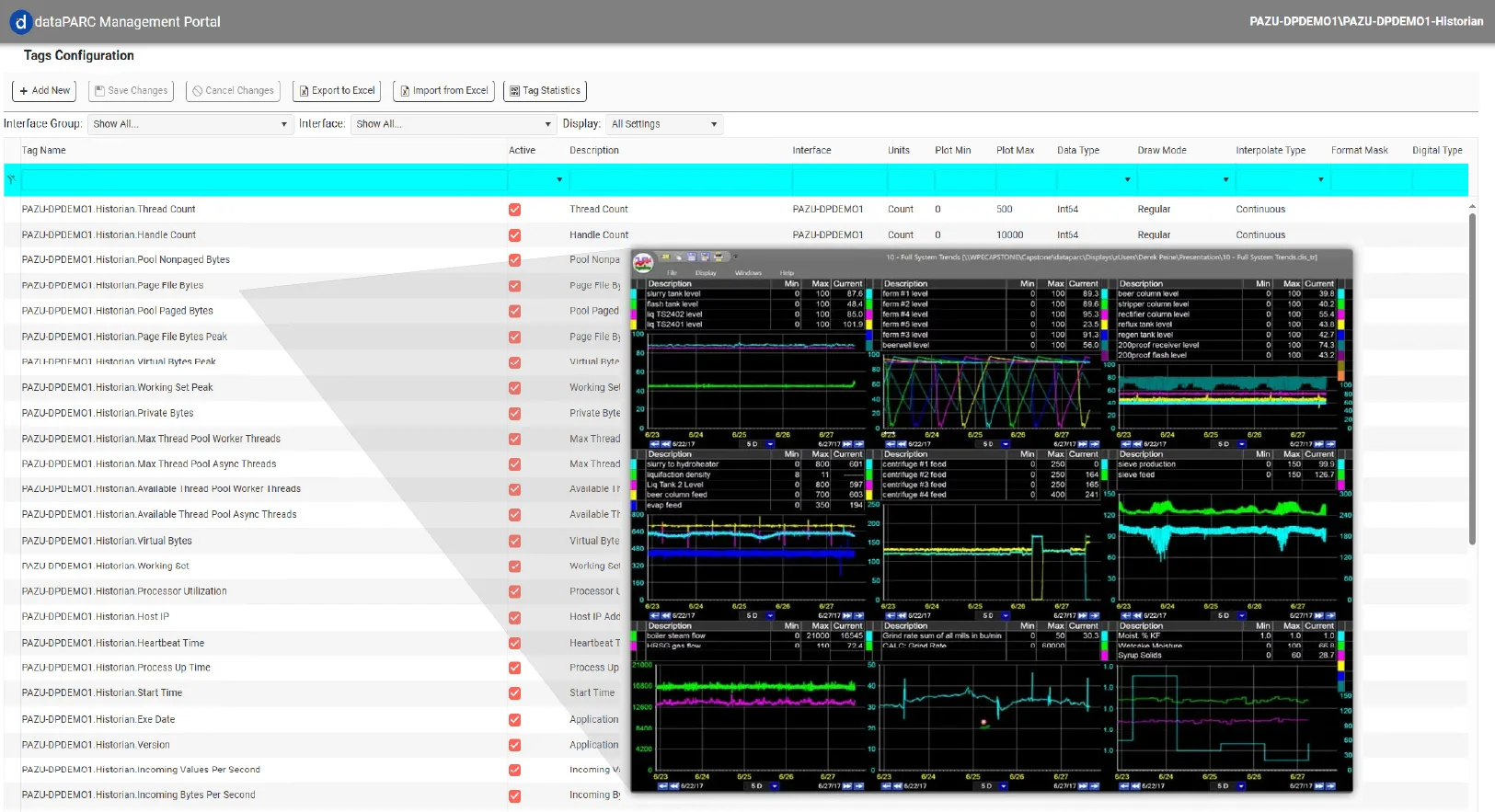

Simple Configuration

Simple configuration accelerates deployment and reduces errors. Adding new tags, modifying collection rates, or adjusting compression settings should be straightforward tasks that plant personnel can handle confidently. Intuitive configuration interfaces, bulk import tools, and auto-discovery features minimize setup time. Your team maintains control and your dependency on vendors decreases.

Quality Vendor Support

Support can turn problems into minor inconveniences rather than crises. When issues arise, responsive technical support with deep product knowledge makes all the difference. Training, user communities, and the availability of professional services all contribute to long-term success. Your questions get answered quickly, challenges get resolved efficiently, and your confidence stays high.

Reasonable Licensing Models

The licensing model makes growth predictable and affordable. Per-person pricing that escalates unpredictably, limits user access to your data, and discourages knowledge. Transparent pricing eliminates budget surprises.

Why dataPARC Makes an Excellent Industrial Historian

Now that we’ve established what makes a good industrial data historian, let’s examine how dataPARC delivers on these essential capabilities and what sets it apart in the market.

The dataPARC Historian is the Industrial Data Historian

High-speed data collection with sub-second capture rates ensures you never miss critical process events. Store-and-forward capabilities guarantee data integrity even during network disruptions. Comprehensive connectivity supports OPC, OPC UA, and native drivers for major control system platforms, making integration straightforward regardless of your automation environment. The dataPARC Historian is designed to optimize large amounts of real-time data for high-speed data collection and performance.

Fast, scalable data historian at a fraction of the cost. Check out the dataPARC Historian.

:Integrated Visualization Platform

What truly distinguishes dataPARC is the tight integration between historian and visualization. Many historical vendors treat trending and analysis as afterthoughts, offering basic charting tools that force users to export data to third-party applications for serious analysis. dataPARC was designed from the ground up as an integrated platform where powerful data collection, storage, and visualization work seamlessly together. Engineers and operators access the same intuitive interface for both real-time monitoring and historical analysis. With PARCview, users can see and use all you data in one place from Historian to MES and LIMS.

Production monitoring with dashboards and trends makes the dataPARC historian even more powerful.

Performance You Can Count On

Performance at scale sets dataPARC apart. Facilities managing tens of thousands of tags across multiple production lines experience consistently fast query performance and responsive trending. Whether you’re viewing the last hour or the last year of data, retrieval happens in seconds. Complex multi-variable comparisons that would bog down lesser historians render smoothly in dataPARC. Your analysis stays fluid. Your troubleshooting stays efficient. Your productivity stays high.

Accessible to All Users

dataPARC’s commitment to usability democratizes data access. Process engineers, operators, quality managers, and maintenance technicians all find the interface intuitive and accessible. Drag-and-drop trending, customizable dashboards, and logical navigation mean less training time and faster time to insight. When everyone in your organization can easily access and interpret process data, the culture shifts from opinion-based to data-driven. Decisions improve across every level.

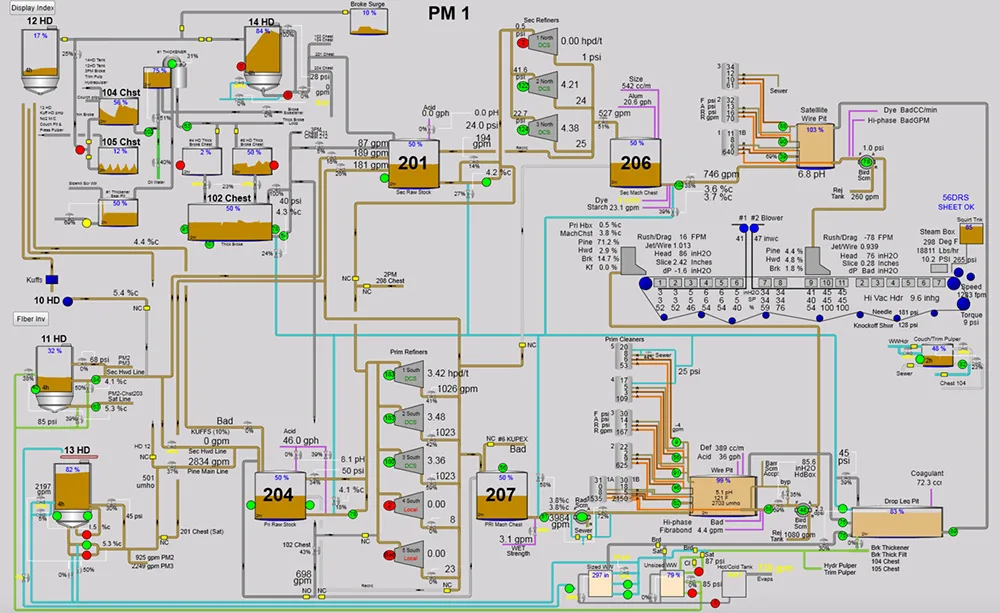

Built for Process Industries

Real-world validation across demanding industries confirms dataPARC’s capabilities. Companies in pulp and paper, chemical processing, food and beverage, mining, and other process industries rely on dataPARC daily for production optimization, quality improvement, and regulatory compliance. The historian runs reliably in harsh industrial environments, handles the complexity of continuous processes, and delivers the performance that 24/7 operations demand.

This graphic illustrates how complex dashboards can get in dataPARC for process industries, from pulp & paper to mining and oil & gas dataPARC can be customized to your process.

Scalability for Growth

The platform grows with your operation. dataPARC supports distributed architectures for enterprise deployments, scales seamlessly as you add production lines or facilities. Customers who started with a single production line have grown to plant-wide and enterprise-wide deployments without hitting performance walls. Everyone who needs it has access to the data, growth stays sustainable and your investment stays protected.

Listening to Customer Needs

dataPARC’s roadmap reflects ongoing innovation. Regular updates bring new capabilities, enhanced security, and improved performance. The company listens to customer feedback and invests in features that solve real operational challenges. Cloud connectivity options, advanced analytics integrations, and mobile capabilities continue to evolve.

Choosing an industrial data historian means choosing a technology partner for decades. dataPARC combines proven reliability, exceptional performance, intuitive usability, and continuous innovation in a platform designed specifically for the demands of process manufacturing.

Conclusion: Evaluating Your Historian Options

Selecting an industrial data historian is one of the most important technology decisions you’ll make for your facility. The right choice enables continuous improvement, supports operational excellence, and protects decades of valuable process knowledge. The wrong choice leads to frustration, limited adoption, and eventually costly replacement projects.

As you evaluate options, use the capabilities outlined in this guide as your framework. Does the historian capture data reliably at the speeds your process demands? Can it integrate seamlessly with your existing automation infrastructure? Will your team actually use it, or will complexity create barriers to adoption? Does the vendor demonstrate commitment to long-term innovation and support?

The cost of choosing poorly extends far beyond the purchase price. A historian that underperforms leads to abandoned initiatives and wasted investment. One that’s difficult to use sits idle while decisions continue to be made on gut feel rather than data.

dataPARC offers a proven path forward. With comprehensive capabilities, intuitive design, proven performance, and a track record across demanding process industries, dataPARC delivers what a modern industrial data historian should be: powerful yet accessible, comprehensive yet manageable, reliable today and ready for tomorrow.

Ready to see how dataPARC can transform your operations? Request a demo to experience the platform firsthand, explore how it integrates with your specific systems, and discover why leading manufacturers trust dataPARC as their industrial data historian. Your journey toward data-driven operational excellence starts with the right foundation. Make sure that foundation is built to last.

FAQ Industrial Data Historians

- What is an idustrial data historian?

An industrial data historian is specialized software that continuously collects, compresses, and stores time-series process data from sensors and control systems in manufacturing operations. dataPARC is an industrial data historain and integrations with visualization and analysis tools, letting users access and analyze historical data through the same intuitive interface they use for real-time monitoring. - How is a historain different from a SCADA system or database?

SCADA systems focus on real-time monitoring and control with limited data retention (typically hours or days), while general databases aren’t optimized for high-frequency time-series data. They struggle with data compression and query performance. Industrial historians, like dataPARC are purpose-built for long-term storage of continuous process data, using specialized compression algorithms and indexing that make retrieving years of high-resolution data fast and efficient. For more, check out Historians vs. SCADA for Manufacturing Analytics. - Does dataPARC support store-and-forward capabilities?

dataPARC uses store-and-forward technology to ensure data integrity and prevent loss during network or server disruption. - Can a new historian backfill my old historain data?

Although we can’t speak for every historain, the dataPARC historian can backfill old historian data. So your site will maintain it’s data even when switching systems.

Building The Smart Factory

A Guide to Technology and Software in Manufacturing for a Data-Drive Plant