Manufacturers are accelerating their investment in AI, but most quickly discover the same challenge: AI can only deliver value if the underlying data infrastructure is ready for it. That’s where an AI enabler comes in. Instead of replacing existing systems or forcing a full digital overhaul, an AI enabler provides the connective tissue that brings plant-floor data, lab results, and enterprise systems together in a way that analytics and machine learning tools can actually use.

This blog explores how dataPARC functions as a powerful AI enabler for manufacturers, helping teams unify their data, build and deploy models faster, and deliver real-time AI insights back to operators where decisions are made.

Ready your Manufacturing Ecosystem with a Fast Data Historian and Process Monitoring

Why Manufacturers Need an AI Enablement Layer

AI and machine learning are seeping their way into every part of manufacturing, from quality prediction to energy optimization. But these models can only deliver value if plants can feed them the right data and then route the results back to operators fast enough for them to make informed decisions. AI systems need data that is accessible, connected across departments, and rich with context, such as production runs, lab values, operator notes, and events.

Most plants do not operate that way by default. Process data lives in one system, lab data in another, maintenance data in a third, and enterprise systems in their own isolated environments. Even when all these sources exist, they rarely speak the same language or share the same structure. That gap makes it challenging to build or deploy models, let alone trust their results in real operations.

This is why manufacturers need an AI enablement layer. It serves as the bridge between OT and IT, integrating process signals, lab results, runs, and events into a unified, analytics-ready environment. Instead of forcing teams to build custom integrations or overhaul existing infrastructure, an enablement layer provides the connectivity and context models require, while also delivering AI outputs back to operators and engineers in real time.

PARCview pulls data from all your systems into one place and can then send it to a third-party AI system for further analysis, with all the data aligned and together.

In short, AI fails on raw data alone. It succeeds when that data is organized, contextualized, and accessible across the plant. An AI enablement layer makes this possible, giving manufacturers a practical, scalable foundation for applying advanced analytics without disrupting day-to-day operations.

How dataPARC Connects Operations to AI and Machine Learning

To make AI useful inside a plant, data must move smoothly between operational systems and the analytical tools that train, validate, and run models. dataPARC provides that connection point by creating a unified data environment that bridges real-time operations with modern AI and ML platforms.

At the foundation is unified connectivity. dataPARC integrates process, lab, maintenance, and enterprise data through OPC, SQL, REST, and cloud interfaces, eliminating the silos that typically separate OT and IT systems. This allows engineers and data scientists to work from the same consistent dataset without building custom connectors or manual workflows.

dataPARC then applies contextualization, aligning raw tag data with production runs, lab results, operator comments, and event histories. This creates a structured, analytics-ready model that is essential for accurate feature engineering, data selection for training, and long-term model performance. AI tools receive clean, consistent inputs rather than fragmented or ambiguous data streams.

Once models are built, dataPARC closes the loop through workflows. Model predictions, confidence scores, or recommended setpoints can be delivered directly into PARCview dashboards, where operators and engineers already monitor their processes. This enables real-time decision support and ensures AI insights are not trapped in other systems or offline reports.

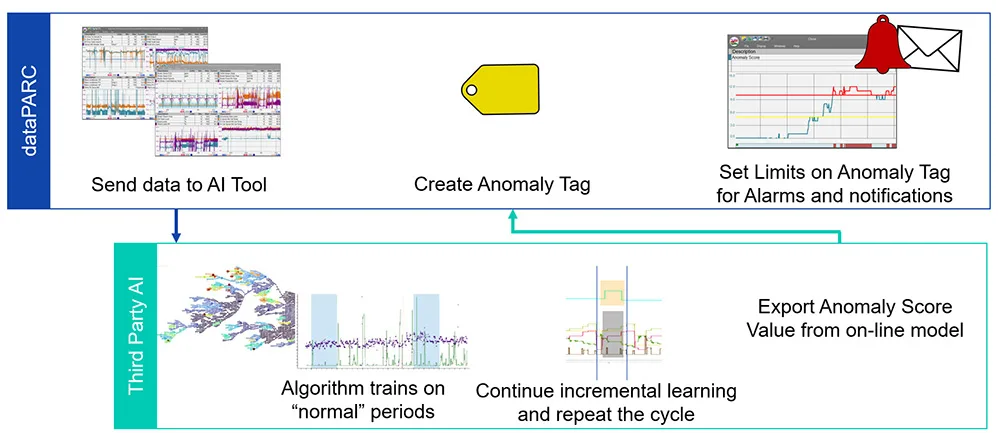

This shows the steps from dataPARC and a third-party AI, with raw data being sent to the AI Software and being inserted back into dataPARC as a tag to have an alarm trigger off high values.

Behind the scenes, dataPARC’s seamless integration ensures that data flows reliably in both directions, from the plant floor to the cloud for model development and from models back to operations for daily use.

The result is a practical, production-ready environment where AI becomes part of everyday plant workflows, not a separate analytical exercise.

Bringing AI Insights Back to Operators in Real Time

To ensure your system is ready for AI, make sure the underlying data is complete, contextualized, and aligned across systems. dataPARC transforms raw plant data into AI-ready intelligence by preparing it for modeling, analytics, and real-time inference.

The platform aggregates information from across OT and IT systems, process tags, lab values, production runs, downtime events, and operator comments, and structures it into a unified model. This eliminates the inconsistent formats, naming differences, and timing gaps that normally slow down model development. Data organized by process area helps contextualize this information.

When models are ready for deployment, dataPARC enables real-time inference by delivering the necessary signals back into the plant environment. Model outputs that can be exported to a folder or file can be automatically imported into a PARCview tag. Therefore, the user can trend the value, set an alarm, or view it in a dashboard. This ensures that AI insights reach operators, engineers, and supervisors in the moment decisions are made.

By turning disconnected data into structured operational intelligence, dataPARC removes one of the biggest barriers to industrial AI adoption: making information usable, consistent, and actionable at scale.

Practical AI Use Cases You Can Deploy Today

Because dataPARC provides unified connectivity, contextualization, and real-time visualization, manufacturers can deploy meaningful AI applications without ripping and replacing existing systems. Here are just a few examples of everyday use cases that you could try:

Predictive Maintenance

- Detect early equipment degradation using anomaly detection or failure-prediction models.

- Insert surface prediction scores directly in PARCview to guide maintenance planning.

Quality Prediction and Optimization

- Connect ML quality models to live production conditions.

- Give operators real-time predictions of off-spec risk and recommended adjustments.

Energy & Utility Optimization

- Use AI to highlight inefficiencies in steam, power, water, or compressed air usage.

- Feed optimization recommendations back to operators for immediate action.

Process Optimization

- Support continuous improvement with models that recommend setpoint adjustments or detect process drift.

- Compare expected vs actual performance side-by-side in PARCview.

Demand Forecasting and Planning

- Integrate forecasting models with production dashboards.

- Align operations with predicted demand, pricing, or supply constraints.

These applications share a common requirement: accessible, consistent, contextualized data. By providing that foundation and delivering insights back into daily workflows, dataPARC helps manufacturers move from exploratory AI projects to real operational results.

Curious what an AI-ready data ecosystem looks like? This video breaks it down

Why Manufacturers Choose dataPARC for AI Enablement

dataPARC stands out because it makes AI practical, usable, and scalable in real industrial environments. Instead of forcing teams into rigid architectures or data-science-only workflows, it empowers operators, engineers, and analysts to work from the same trusted data foundation. Manufacturers choose dataPARC because it delivers:

Built-for-Operations Usability

Designed for engineers and operators, dataPARC provides intuitive tools for visualization, troubleshooting, and decision support. AI insights become part of the existing workflow, not an isolated analytics project.

Scalable, Trusted Infrastructure

From a single plant to multi-site enterprise deployments, dataPARC reliably handles high-resolution data, long-term storage, and hybrid architectures. It supports on-premise, cloud, and mixed environments without compromising performance or control.

Unified OT–IT Connectivity

dataPARC integrates SCADA, DCS, lab systems, MES, ERP, and cloud analytics platforms into a single environment. This unified view allows AI models to access the full operational context they need.

Seamless Integration With AI/ML Tools

Whether teams use Azure, Databricks, Python, Snowflake, or internal data-science pipelines, dataPARC delivers clean, contextualized data for training and inference. Model outputs flow back into PARCview for real-time operationalization.

Reliability Proven Across Industries

dataPARC is trusted in pulp and paper, chemicals, refining, power generation, food and beverage, and beyond. Plants rely on it for uptime, data integrity, and the ability to scale AI efforts without rebuilding existing systems.

A Practical Path to AI Adoption

Instead of requiring a full digital overhaul, dataPARC meets teams where they are. It bridges current operations with advanced analytics, making AI adoption incremental, achievable, and aligned with day-to-day production needs.

Check out dataPARC’s real-time process data analytics tools & see how better data can lead to better decisions.

FAQ: dataPARC as an AI Enabler for Manufacturing

- What does it mean for a platform to be an “AI enabler” in manufacturing?

An AI enabler provides the underlying data infrastructure required for AI and machine learning to work effectively. This includes connecting OT and IT data, contextualizing signals, storing high-resolution history, and delivering clean, accessible datasets to analytics tools. dataPARC does this by unifying process, lab, and enterprise data and making it AI-ready without disrupting ongoing operations. - Do I need to replace my existing systems to use AI with dataPARC?

Not necessarily, with dataPARC, it has a Historian; the integration and visualization layer, PARCview, sits alongside your existing historians, DCS/PLC networks, lab systems, and enterprise databases. It acts as a unifying layer rather than a replacement. This allows manufacturers to adopt AI incrementally, building on current infrastructure while modernizing their data environment at their own pace. - What types of AI use cases can dataPARC support today?

dataPARC is used in a wide range of AI-driven applications, including predictive maintenance, quality prediction, process optimization, emissions monitoring, energy balancing, demand forecasting, and more. Its contextualized data allows these use cases to integrate directly into daily operations. - Can operators and engineers actually use AI insights inside PARCview?

Yes. Model predictions, recommended settings, anomaly scores, or quality estimates can be displayed directly in PARCview dashboards. This allows operators to see AI guidance in the context of real-time trends and equipment data, enabling faster, more confident decision-making. - How does dataPARC scale as AI adoption grows?

The platform is built for long-term scalability, supporting everything from single-facility deployments to enterprise-wide systems. It manages expanding tag counts, growing data volumes, and additional modeling workloads without compromising performance. As more AI applications are introduced, dataPARC becomes the centralized data backbone that keeps everything aligned and accessible.