When it comes to quality control in manufacturing, reacting after a defect occurs is often too late. Statistical Process Control (SPC) offers a smarter approach, using real-time data to monitor variation and catch problems early. But control charts alone aren’t enough. To truly stay ahead of process shifts, manufacturers rely on a set of proven SPC rules and SPC alarms that flag subtle warning signs before they escalate.

Learn how to keep processes in check with dataPARC’s powerful limit and spec monitoring tools.

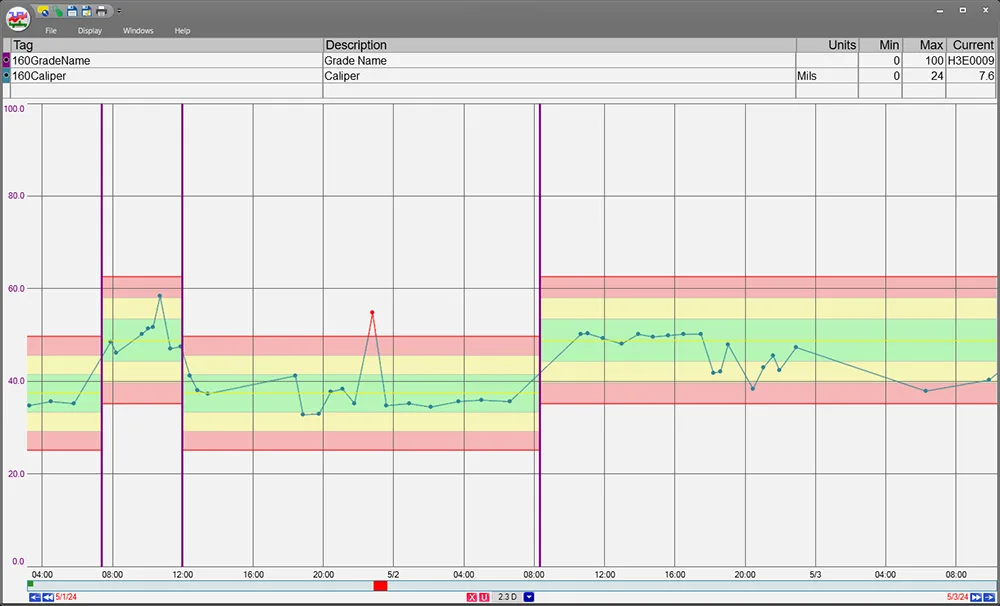

Statistical Process Control (SPC) is a data-driven method used by manufacturers to monitor, understand, and reduce process variation. By utilizing control charts that plot key process data (like temperature, pressure, or flow rate) against upper and lower control limits, SPC helps identify when a process is operating normally or when it’s deviating from the expected behavior. When implemented effectively, SPC not only improves product quality and reduces waste but also enables teams to detect issues early, preventing costly defects.

But how do you know when it’s time to act? That’s where SPC rules come in.

SPC Rules: What They Are and Why They Matter

SPC rules define patterns in your data that indicate something unusual is happening—even if your data is still technically within the control limits. These rules catch both big and small changes, helping quality teams act early.

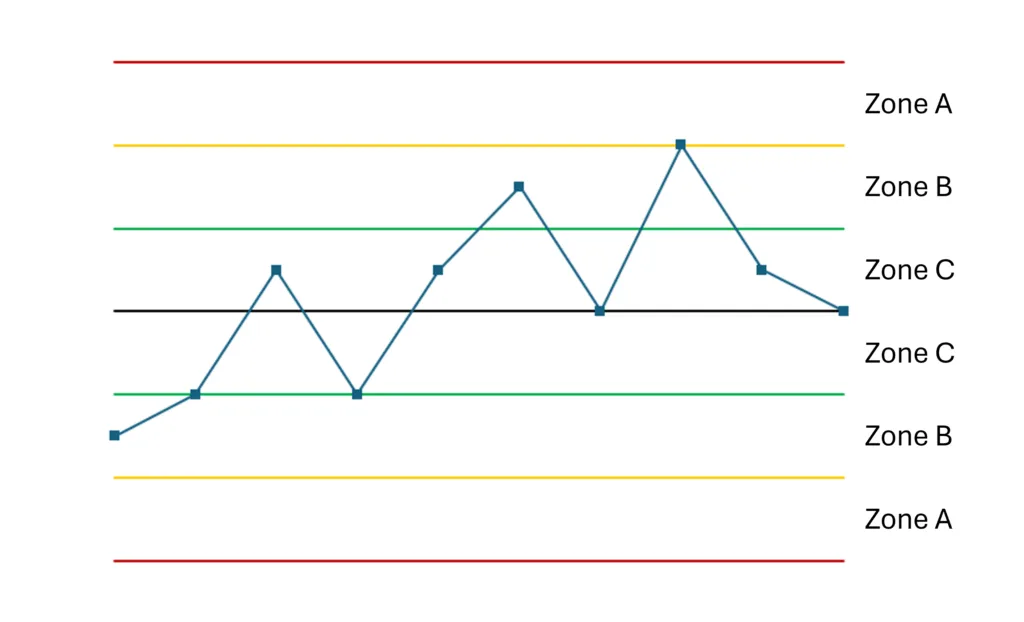

To define rules, deviations are described by zones. Zones are bands around the average Zone A is 2σ to 3σ, Zone B is 1σ to 2σ, Zone C is within 1σ.

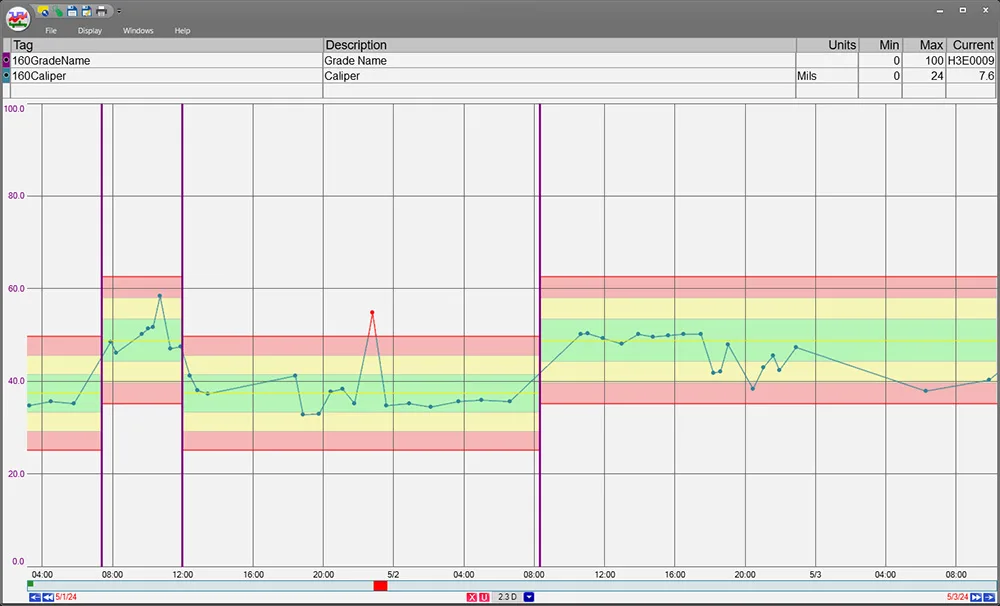

Variance is visualized using zones shows how close the process is to the target.

Here’s a breakdown of the most commonly used SPC rules, what triggers them, and why you should care:

Outside Control Limits

Triggers an alarm when a point falls outside the upper or lower limit (±3 standard deviations). This usually signals a major shift or special cause that needs immediate investigation, such as equipment failure, raw material issues, or human error.

2 of 3 Points in Zone A

Alarms if two out of three consecutive points fall in Zone A (between 2σ and 3σ from the centerline). Suggests a medium-sized shift that could lead to defects if left unaddressed.

4 of 5 Points in Zone B

Alarms if four out of five points fall in Zone B or farther from the center (between 1σ and 3σ). Detects smaller, gradual shifts in the process, often early indicators of machine wear or subtle process drift.

9 Points on One Side of the Centerline

Alarms when nine consecutive points are either all above or below the average. A small but consistent shift, often caused by calibration issues or changes in raw material.

6-Point Trend (Up or Down)

Alarms if six points in a row are continuously increasing or decreasing. Indicates a process drift, such as a slow leak in a valve or warming equipment.

14-Point Oscillation

Alarms if 14 points alternate direction. Points to systematic or artificial variation, possibly caused by an operator over-adjusting the process.

15 Points in Zone C

Alarms if 15 consecutive points fall within one standard deviation (Zone C). Suggests overly consistent data, potentially from stratified sampling or data manipulation. It may also mean control limits are too wide.

5 Steps to Respond to an Alarm

SPC rules are most useful if they lead to action. When a violation happens, here’s a typical workflow for manufacturers:

1. Log the Event

The first step in the process is to log the events. It is important to document the who, what, where, when, and why of the matter. What piece of equipment, why was it starting to drift, when did this happen, who was on shift?

2. Investigate the Root Cause

Once the event is logged, identify why the event occurred. Structured problem-solving tools such as Pareto analysis help dig into the root cause of the issue. What caused the event to be different than normal variation?

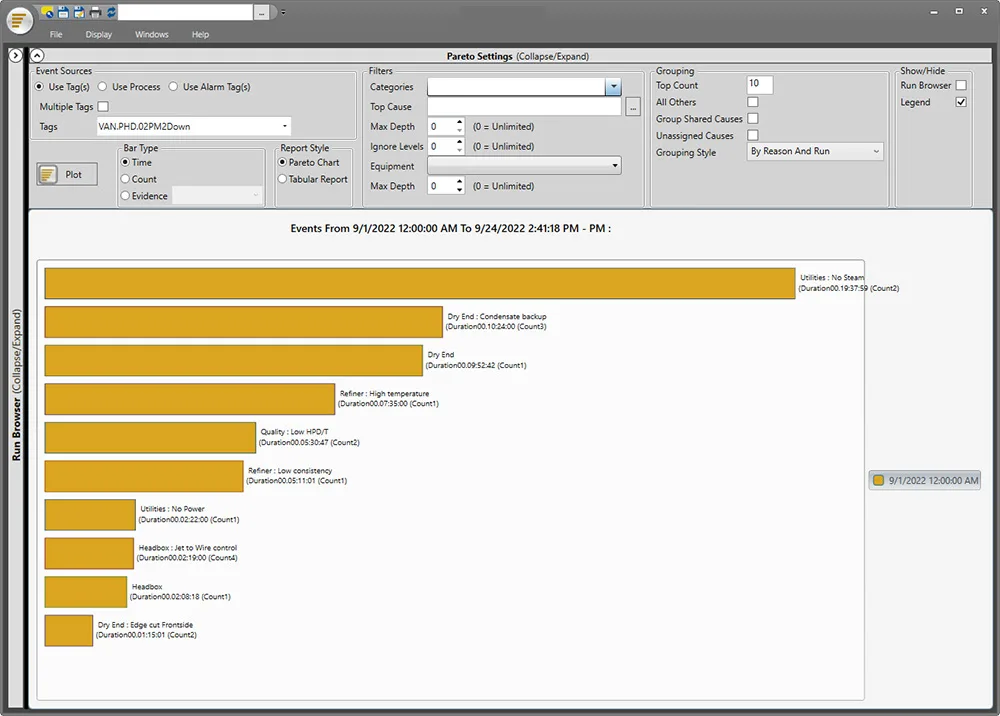

Tools like Pareto can be used to help diagnose the root cause of an issue.

3. Take Corrective Action

After identifying the root cause, take corrective action to address the specific issue. This may mean adjusting settings, repairing equipment, discarding defective material, or retraining staff. Don’t just treat the symptoms, but address the root cause of the issue.

4. Implement Preventive Measures

Corrective action will solve the immediate issue, but preventative measures will prevent the issue from arising again. This may include updating standard operating procedures, modifying equipment settings, improving maintenance schedules, or introducing automated controls. If the issue arose from human error, revising policies or retraining staff may be required.

5. Monitor the Results

After corrective action has been taken and preventative measures have been implemented, continue to monitor the process to confirm their effectiveness. Watch for new recurring patterns or unintended consequences. Ensure the control charts have returned to normal and are steady. Monitoring the situation after action has been taken will allow you to make sure the issue has truly been resolved.

Benefits of SPC Rule Monitoring in Manufacturing

Using SPC rules allows manufacturers to move from reactive to proactive quality control. Implementing SPC rules enhances manufacturing in the following ways:

- Early Detection of Variation: Identify trends before they lead to defects.

- Data-Driven Decisions: Reduces guesswork and reactive firefighting.

- Cost Reduction: Minimizes scrap, rework, and warranty claims.

- Increased Productivity: Stabilized processes result in more predictable throughput.

- Quality Assurance: Meets customer requirements more consistently.

Implementing statistical process controls helps manufacturers reduce variance in their processes.

These rules collectively help manufacturers maintain a state of statistical control while being agile enough to respond to emerging trends or systemic issues.

What This Means for Manufacturers

For manufacturers, SPC rules aren’t just about compliance; they’re essential tools for building a smarter, more responsive operation. When used effectively, these rules give teams the ability to detect subtle shifts, respond quickly to potential issues, and maintain consistent product quality without unnecessary intervention. Rather than relying on intuition or waiting for defects to appear, manufacturers gain a clear, data-backed view of how their processes are performing. This means fewer surprises, better decision-making, and a stronger foundation for continuous improvement.

FAQ: Spec Alarms

- What is zone A?

Zone A is the area between 2 and 3 standard deviations away from the average. Too many points in zone A represent a significant shift in the process. - What is σ?

σ is a standard deviation, how much variation from the average in a standard data set. In SPC, control limits are usually 3 standard deviations from the average, which contains over 99% of expected variation. - What does SPC mean?

SPC means Statistical Process Control, a quality control method that uses statistical tools to monitor and manage process performance. - Why would you want a process to alarm if it is within control limits?

Even data within the control limits can indicate shifts in the process. SPC rules catch early signals before a significant process shift. - What action should be taken when an SPC rule is violated?

Log the event and investigate the root cause. Take corrective action and implement preventative measures to reduce the likelihood of the issue happening again. Monitor the results of your action to ensure the process has improved.

Mastering Manufacturing Metrics

The Ultimate Guide to Establishing, Measuring, & Reporting KPIs for Peak Plant Performance