Process Engineering Software

Everything You Need to Achieve Peak Plant Performance.

dataPARC is a comprehensive solution for manufacturing process optimization. Improve efficiency, productivity, sustainability, and asset reliability with the industry’s leading process data analytics and visualization toolkit.

Versatile Process Engineering Toolkit

Collect

Collect data from various sources in your plant and store time-series data for high-speed retrieval.

Connect

Integrate all your plant data to eliminate data silos and establish a single source of truth.

Analyze

Perform root cause analysis and discover opportunities for process optimization.

Operationalize

Maintain optimal operating conditions with real-time monitoring, control charts, alarms, & reporting.

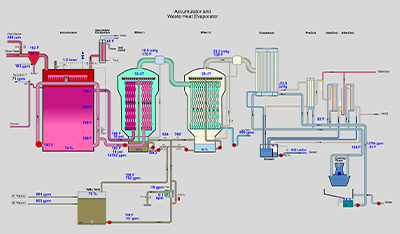

Process Displays

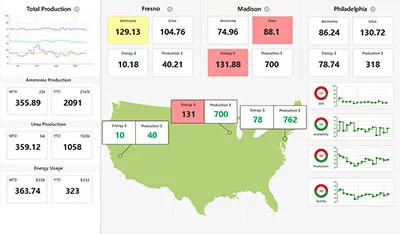

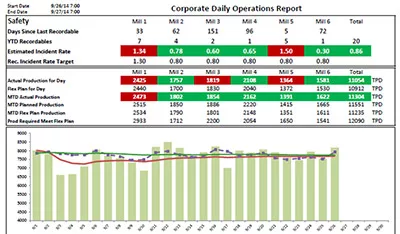

KPI Dashboards

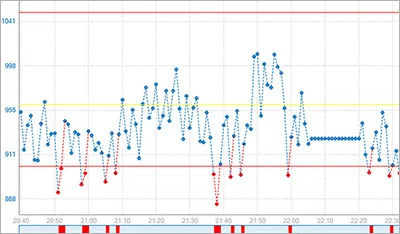

SPC Charts

Advanced Trending

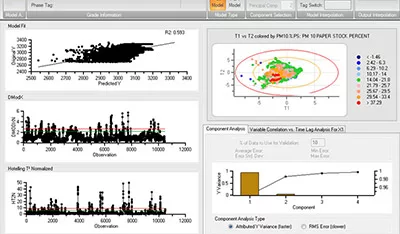

Predictive Modeling

Reporting

Smart Alarms

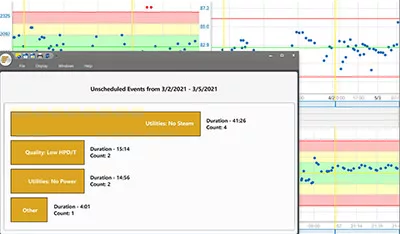

Downtime Tracking

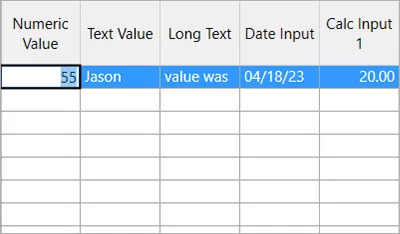

Manual Data Entry

Process Engineering Tools

Monitor, Troubleshoot, & Optimize Your Processes

Turbocharge your troubleshooting efforts and quickly find opportunities for process optimization.

- Find the root cause of process interruptions quickly.

- Reduce variability in costs & quality.

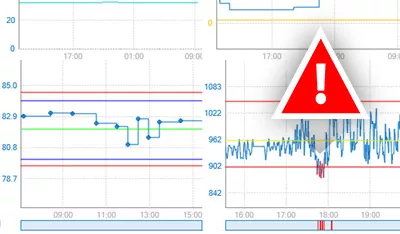

- Minimize downtime with predictive models & smart alarms.

- Compare current and historical data to identify performance trends.

IT/OT Data Integration

Establish Your Single Source of Truth

PARCview provides a single source of truth for all your manufacturing data. Aggregate disparate data from machines and manufacturing systems such as ERP, MES, lab, & quality systems, to develop the insights that drive continuous improvement.

- Integrate data from any source.

- Aggregate data from facilities across the globe.

- Combine disparate data into a single trend, dashboard, or report.

- Connect via XML, SQL, Web Services, OPCHDA, & more.

- Leverage existing historians: OSIsoft PI, IP.21, Honeywell, GE, Aveva, etc.

Find The Root Cause Faster

Mine richer insights from your data with dataPARC’s industry-leading set of ad-hoc root cause analysis & trending tools.

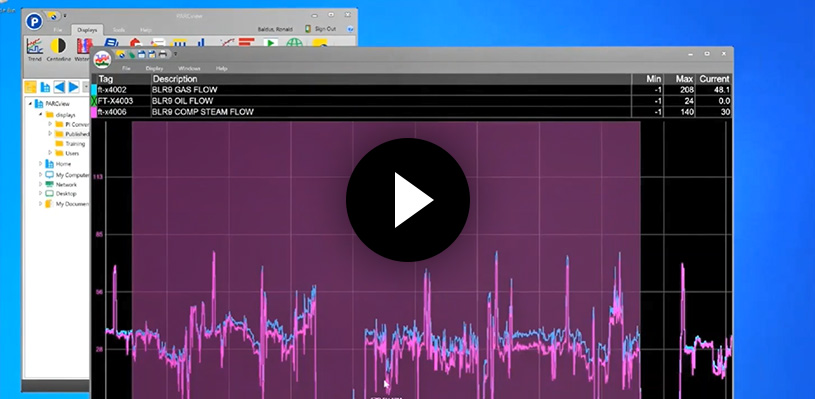

Faster Troubleshooting

How quickly can you diagnose trouble spots at your plant? It takes only 4 minutes to identify the origin of a customer’s boiler efficiency problem using dataPARC’s data visualization tools.

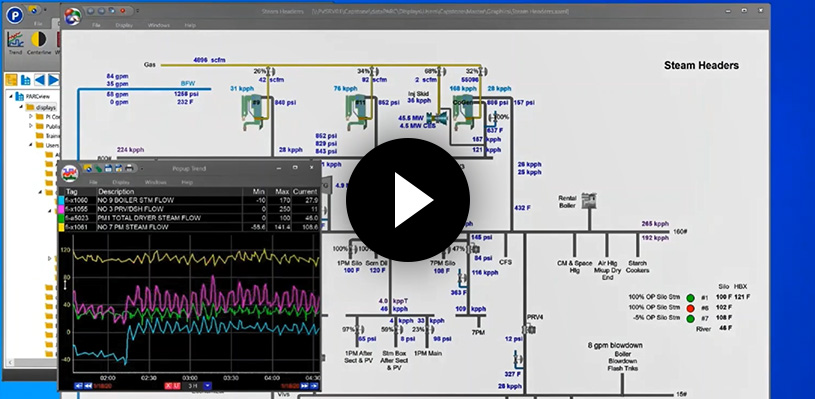

Insightful Process Displays

Optimize processes from the control room. Check out how we use system control room display to identify a problem with a pesky pressure reducing valve.

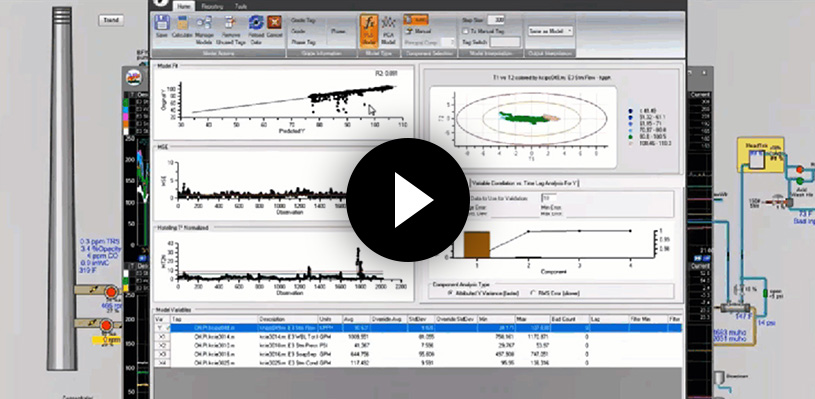

Predictive Asset Management

See how we use dataPARC’s advanced analytics tools to quickly build a predictive steam flow model to provide greater process visibility while the steam flow indicator was down.

Driving Industrial Digital Transformation Success for 25+ Years

Instead of having only lab people using the lab database and only engineering using the process information, it’s all come together. The data is all available to operations, engineering, & managers.

Ryan Sullivan

Production Engineer

We consume nearly a dozen external data sources that help us enrich our data: weather data, power data, pricing data… dataPARC allows us to get more value of what we already have.

Tyler Fedun

Manager IT Operations

We were trying to optimize the largest facility in our company and dataPARC allowed us to overlay data – both lab and process – to break down perceptive barriers and make data-driven decisions.

Stan Case

Plant Manager

Analytics for Everyone

Designed to be easy to use by individuals from the plant floor all the way up to enterprise management, dataPARC democratizes your plant data and allows everyone to contribute to the data-driven optimization of your manufacturing processes.

Plant Floor

24/7 Decision-Making

Make it easy for operators to monitor and record process data in real time.

Engineering

Process Troubleshooting & Optimization

Faster root cause analysis & predictive modeling.

Quality & Lab

Measurement & Control

Troubleshoot & prevent quality issues & minimize waste

IT Operations

Enterprise-wide Data Integration

Connect data from disparate machines & manufacturing systems.

Senior Management

Strategic Decision-Making

Monitor enterprise-level KPIs & site-level process and equipment statuses.

Data Scientists & SMEs

Advanced Analytics & Asset Analysis

Establish standards, KPIs, and best practices across the organization.

Common Applications

dataPARC’s plant analytics tools will give you the insights needed to quickly optimize your manufacturing processes.

Grade Troubleshooting

Profile Analysis

Energy Monitoring

Asset Monitoring

LIMS

Operation Envelope & Setup

Production Cost Monitoring

Production Loss Tracking & OEE

Soft Sensors

SPC / SQC

Stock Tracking

Tank Inventory & Modeling

Core Solutions

dataPARC is a flexible industrial analytics toolkit built upon the promise of easy data acquisition & integration. dataPARC’s core building blocks can be used to build any applications to meet your needs.

Trending & Root Cause Analysis

Quickly analyze and troubleshoot to find the root cause of process & equipment issues.

Process Optimization

Analyze, adjust, and control processes to drive improvements in quality & efficiency.

Production Monitoring

Monitor manufacturing production KPIs & downtime events for enterprise-wide visibility.

Quality Control

Real-time quality control tools for continuous or batch manufacturing processes.

OEE Tracking

Analyze, calculate, & report production loss from downtime, lost opportunities, & process slowdowns.

Download Our Overview Datasheet

Click the link below to receive a FREE overview on the benefits of using dataPARC to transform critical data into visual information for timely decision-making.