The #1 Honeywell Uniformance PHD Alternative

Collect and access process data from a variety of sources to seamlessly troubleshoot and analyze current operating conditions. dataPARC offers everything you expect

from a mission critical data historian product including essential accessibility, performance, and security; making it the #1 alternative to Uniformance PHD for time series data storage.

High-Speed Time Series Data Storage

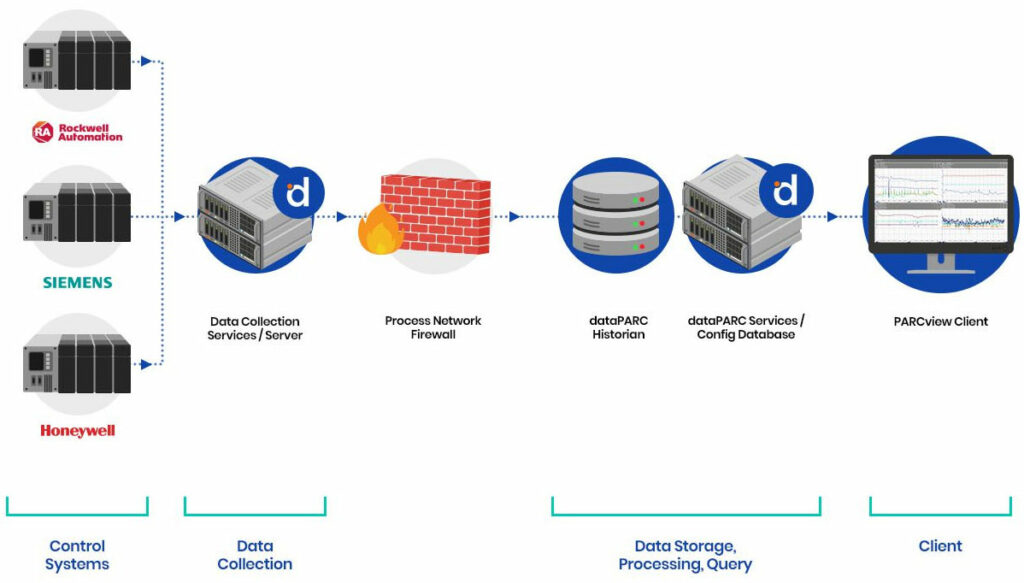

Collect & record high-frequency industrial process data from every automation and control systems in your plant. Then share critical data with the PARCview client or third-party applications to troubleshoot issues using robust reporting and advanced analytics solutions. Capabilities can even be scaled up to the enterprise level to make multi-site data analysis easier and more efficient.

Comprehensive Industrial Process Historian

PARCserver collects & records high-frequency industrial process data from automation and control systems in your plant. Capabilities can even be scaled up to the enterprise level to make multi-site data analysis easier and more efficient.

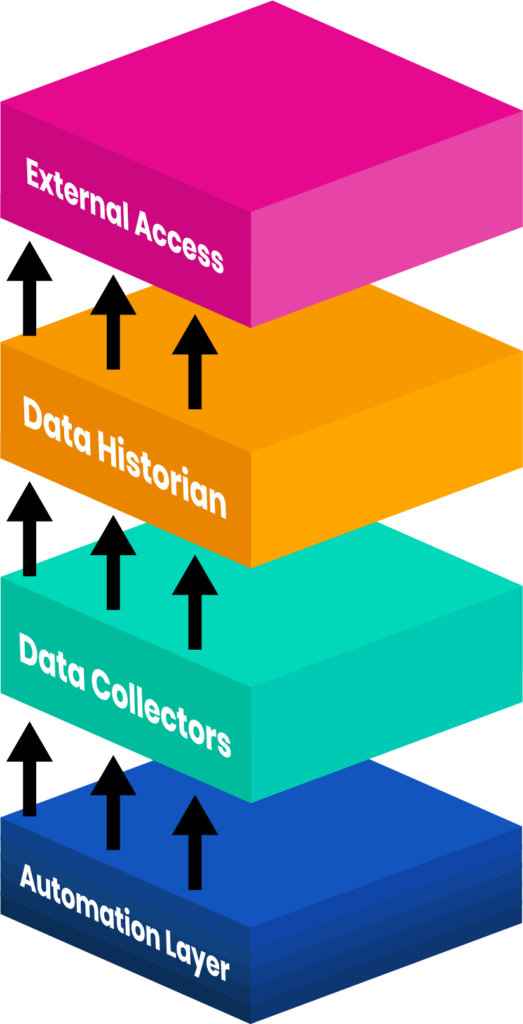

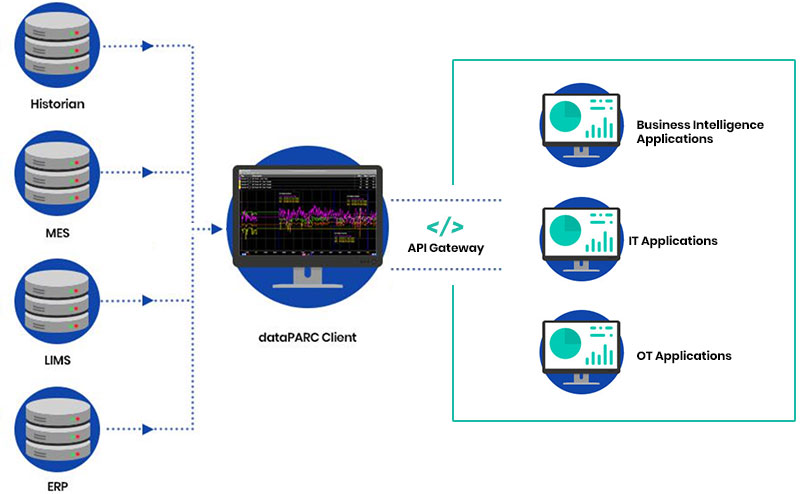

External Access

PARCserver includes several methods for easily connecting external applications to the Historian data. So it’s easy to interface your favorite reporting package or Advanced Analytics solution.

Data Historian

The PARCserver suite of applications is the powerhouse behind the speed and efficiency with which dataPARC products retrieve and display data.

Data Collection

Data collectors utilize “store and forward” technology to buffer data, ensuring maximum integrity. Hundreds of OPC and custom servers are available to interface with your automation layer.

Automation Layer

PARCserver is capable of acquiring high frequency data from all the automation and control systems in the plant. These systems include PLCs, DCSs and others.

Dive Into The Data

dataPARC’s process historian is designed to optimize large amounts of real time data for high-speed data collection and analytics performance. Connect all your systems to collect data at a single site, or aggregate data across multiple sites for enterprise-wide visibility.

- Combine IT & operations data for better visibility.

- Collect PLC & control data.

- Connect to standard SQL databases for lab & quality data.

- Integrate IT data from MES, etc.

- Share data between sites easily.

Flexible Enterprise Architecture

Make all data perform like it’s local. dataPARC’s process data historian is designed for increased operational performance and reduced data and administration costs. Achieve improved efficiency and productivity by switching from Uniformance PHD with streamlined resources that give you access to your manufacturing data when and where you need it.

Smart Data Collection

PARCserver leverages machine learning to automatically roll-up or compress data based on usage, freeing up critical disk space.

Minimize Bandwidth on WAN

Reduce network load by offering higher-performance, low-bandwidth data to corporate users until high resolution site-level data is requested.

Smaller Corporate Footprint

Provide optimized, high-performance data for enterprise access, reducing the need for costly hardware infrastructure at corporate HQ.

Rapid Remote Access

Quickly view optimized aggregate data at corporate & remote sites, while maintaining instant access to lossless, high resolution production data.

Auto Archiving

PARCserver povides instant online access to 100% of your historical data while also automatically archiving older (5-10 years) data to less expensive storage drives.

Scale Tags at Lower Cost

Get an Enterprise-class historian at a fraction of the cost. PARCserver is a cost-competitive process data historian suitable for all systems.

Push Processed Data Anywhere

Analyze, filter, & generate modeled values from your data with dataPARC, then use our single-point API to push the processed data to your current IT, OT, or business intelligence applications.

“We consume nearly a dozen external data sources that help us enrich our data: weather data, power data, pricing data… dataPARC allows us to get more value of what we already have.”

Tyler Fedun, Director IT Operations – Energy Transfer

The World’s Largest Manufacturers Depend on dataPARC

Related Solutions

Take control of critical plant performance data with dataPARC’s real-time data visualization and analytics software. Tackle industrial data challenges with PARCview’s out-of-the box functionality.

Data Integration

Establish a single source of truth for all your raw production data. Historian, ERP, MES, lab, & more.

Quality Control

Real-time quality assurance and control tools for continuous or batch manufacturing processes.

PARCserver Historian Data Sheet

Learn more about the data historian software that allows you to collect data from across the plant and easily connect to your favorite reporting package or advanced analytics solution.