Production Cost Monitoring

Apply PARCview’s visualization tools to production cost information to draw correlations between process operations and financial performance.

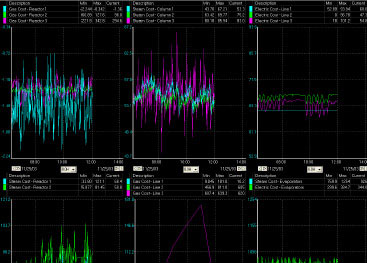

Reduce Energy

Minimize energy costs by monitoring the consumption of all utilities (electricity, water, natural gas, compressed air, steam etc.).

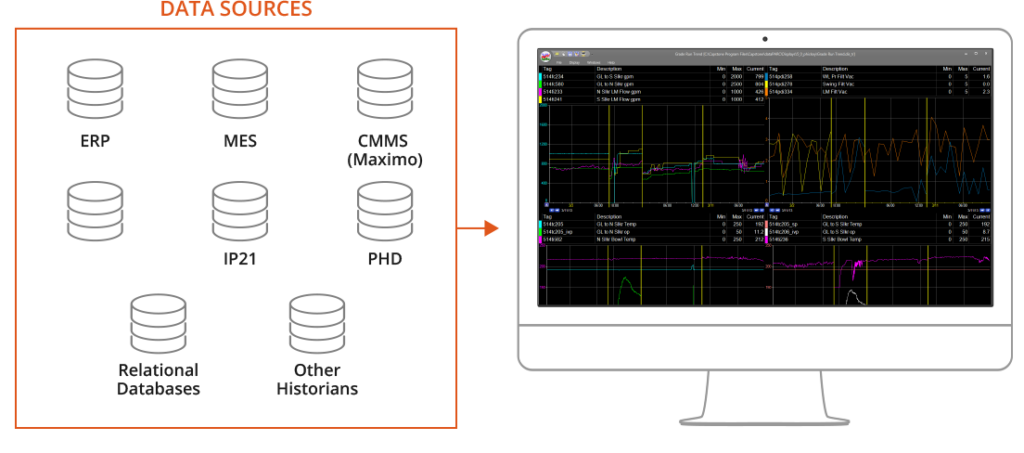

ERP Interface

A two-way data interface with accounting software, such as SAP, provides direct access to current cost data. Build logic-based calculations with process variables to produce tags that track the usage rate and cost of raw materials, chemicals, and utilities.

Real-Time Monitoring & Escalation

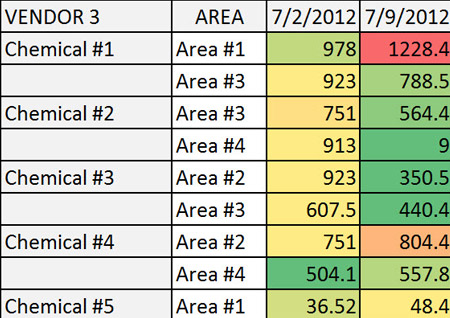

View production cost information in real time and make timely data-driven decisions. Monitor against budgeted values by applying limits to cost tags and triggering alarms for excursions. Automatically deliver timely notifications to escalate the issue to the appropriate personnel. When important categories, such as chemical or energy costs, are continuously monitored, action can be taken immediately instead of wating for dated reports.

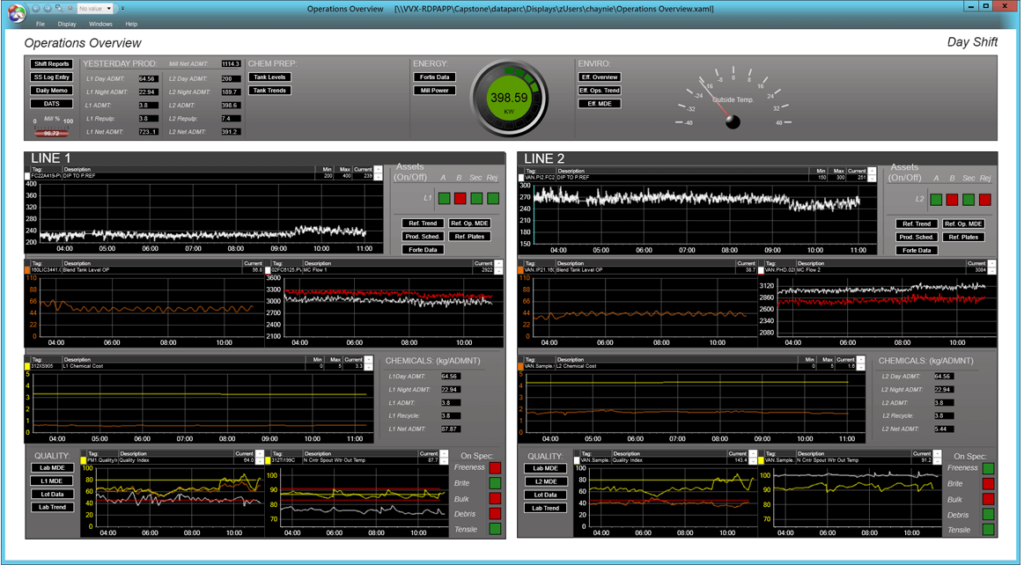

Cost Reporting & Gap Analysis

Through combined application of PARCpde’s data aggregation and PARCview’s tag limits, view statistical information from process runs or fixed time periods, such as production days or shift schedules, and calculate the difference from a budget or other standards. Construct production cost dashboards with the PARCgraphics Designer to get the big picture.

Accomodating Instrumentation Challenges

For process variables that cannot be automatically measured, PARCview’s Manual Data Entry system provides a solution like chemical totes that aren’t connected to the DCS. For example, chemical usage can be tracked every shift or day, instead of relying on monthly cycle counts. Having a current digital inventory helps identify small changes that would otherwise go unnoticed. Tie MDE records to grade or product runs to quickly find outliers that influence cost on a run-by-run basis.

Want To Learn More?

Click the links below to recieve a FREE PDF on the solutions dataPARC has to offer on Real-Time Production Cost Monitoring.